Kev tsim khoom lag luam yog ib qho ntawm cov kev lag luam dynamic tshaj plaws. Niaj hnub no, muaj ib tug relentless thawb los txhim kho tag nrho cov precision thiab raug thiab cov txheej txheem zoo li hlau EDM uas xa precisely uas tsis muaj dab tsi luv luv ntawm transformative rau kev lag luam.

Yog li, Wire EDM yog dab tsi, thiab vim li cas nws thiaj suav tias yog kev hloov pauv kev ua si rau kev tsim khoom? Cov ntawv hauv qab no yuav ua tib zoo saib cov hauv paus ntawm cov txheej txheem tsim khoom zoo nkauj no nrog rau kev siv thoob plaws kev lag luam sib txawv.

Kev Taw Qhia luv luv rau Hlau EDM

Hlau Hluav Taws Xob Discharge Machining (EDM) tau pib ua ntej xyoo 1940 los ntawm ob tus kws tshawb fawb Soviet uas thawj zaug eroded hlau nrog hluav taws xob tawm. Cov thev naus laus zis pom kev nce qib tseem ceeb hauv 60s thiab 80s, dhau los ua lag luam ntau dua hauv kev tsim khoom. Los ntawm lub 90s lig, nrog IT thiab CNC kev txhim kho, xaim EDM tshuab tau dhau los ua computerized, boosting lawv efficiency thiab precision.

Niaj hnub no, Hlau EDM yog qhov tseem ceeb hauv kev lag luam xws li Aerospace, Automotive, thiab Kev Kho Mob, paub txog kev xa cov qauv tsim thiab cov ntaub ntawv nyuaj tsis sib xws los ntawm cov txheej txheem machining.

Cov Txheej Txheem Hlau EDM

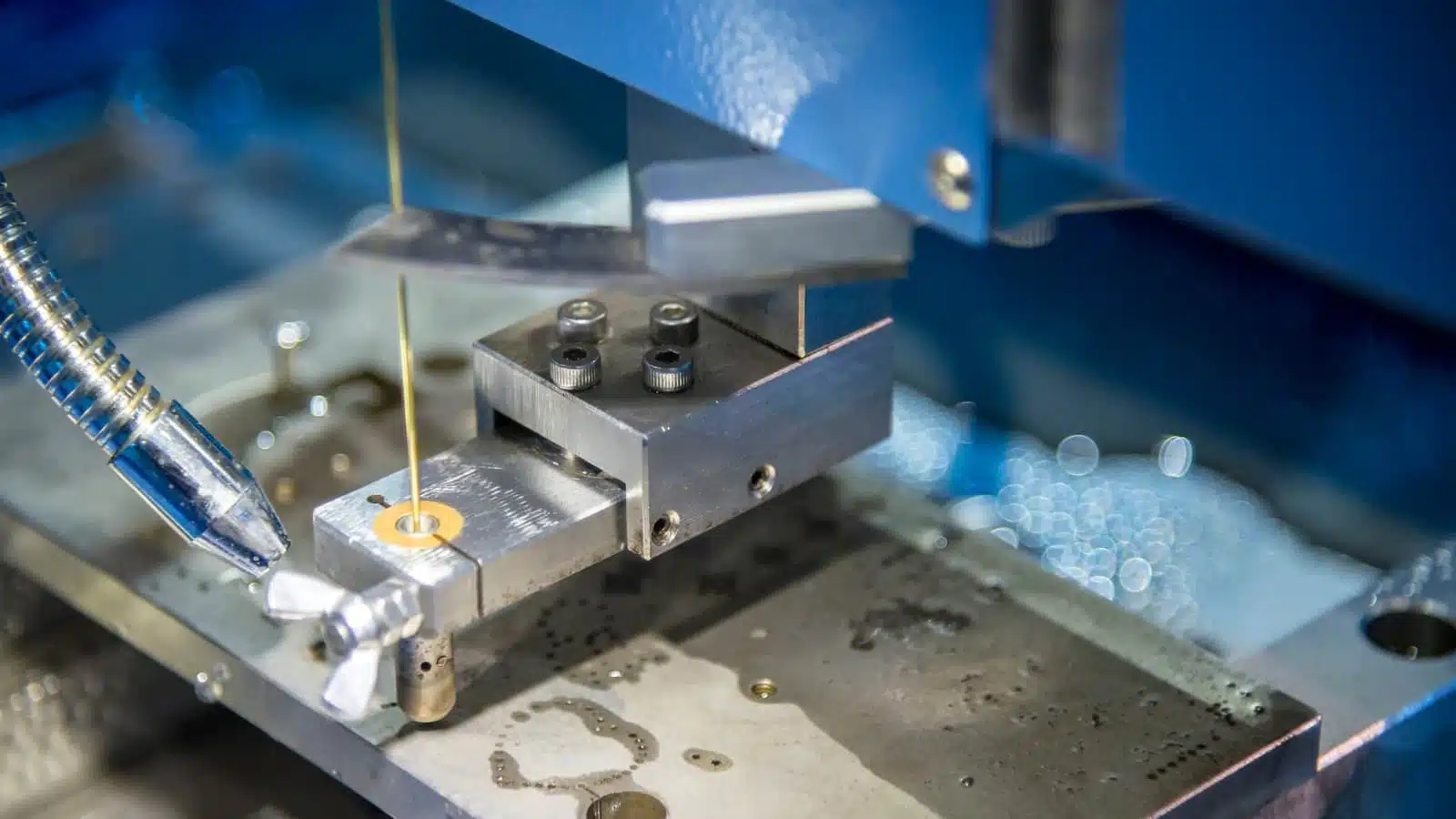

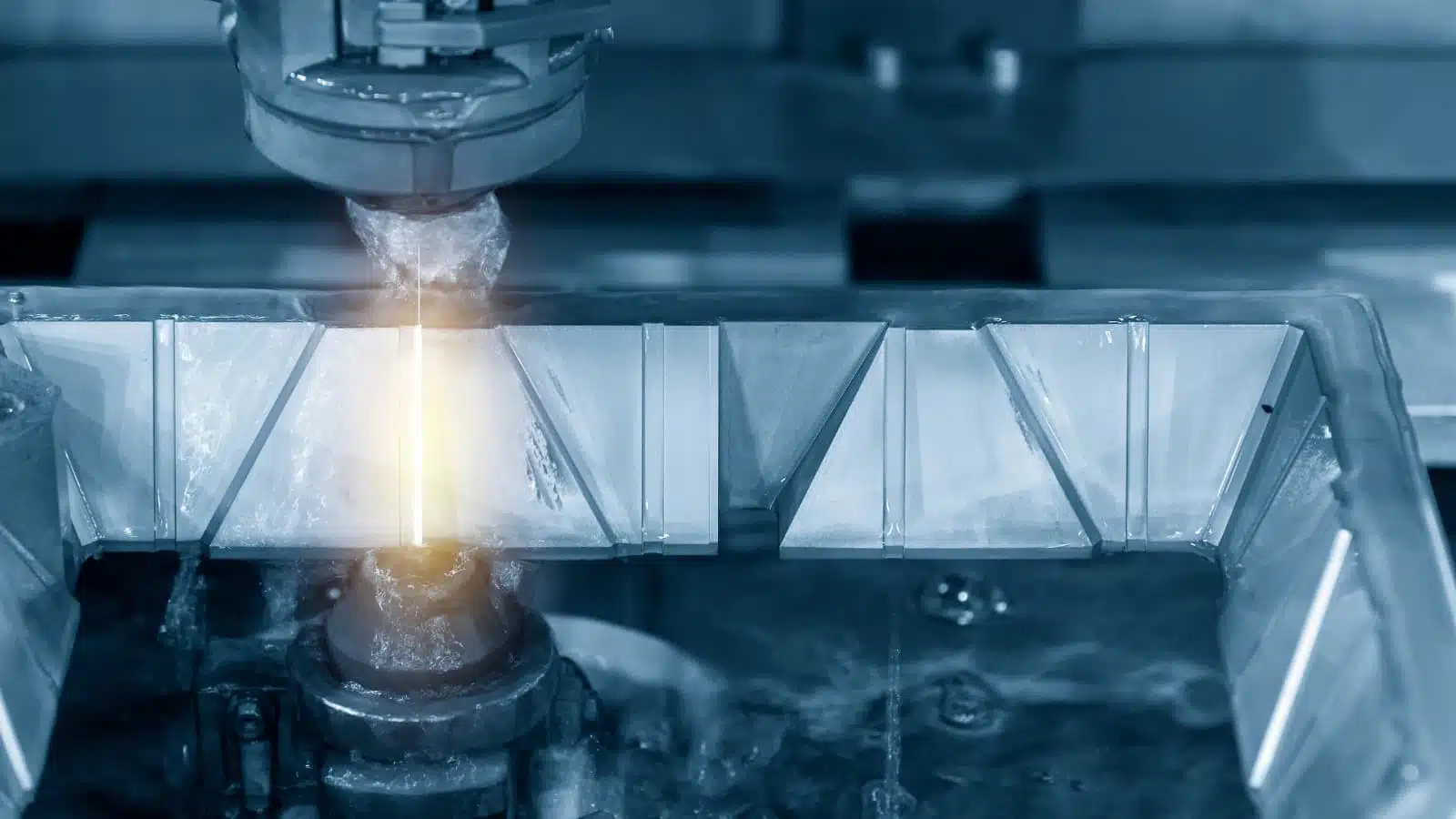

Hlau Hluav Taws Xob Discharge Machining (EDM) yog ib txoj hauv kev uas siv cov hluav taws xob tswj hluav taws xob kom yaj qhov me me ntawm cov khoom ua haujlwm. Cov hlau electrode, feem ntau yog ua los ntawm tooj dag lossis zinc-coated cov ntaub ntawv, tsim lub txim no thiab txav mus rau hauv txoj kev npaj ua ntej. Nws qhov zoo dua? Nws ua haujlwm yam tsis muaj kev sib cuag ntawm lub cev, tiv thaiv kev puas tsuaj lossis cov cim ntawm ob qho tib si workpiece thiab lub cuab yeej.

EDM ua haujlwm li cas

EDM hinges ntawm thermal zog los ntawm hluav taws xob tawm. Qhov no tso tawm heats lub workpiece mus rau nws melting point, tsim me me plasma raws. Cov channel no, feem ntau micrometer-loj, tuaj yeem ploj mus sai.

Cov txheej txheem EDM tshwm sim hauv qhov nruab nrab dielectric, feem ntau deionized dej. Cov kua dej no ua rau cov khoom ua haujlwm txias thiab tshem tawm cov khoom vaporized, pab ua haujlwm tsis tu ncua.

Qhov tseem ceeb ntawm Hlau Electrode

Ua raws li ob qho tib si cutter thiab tus neeg xyuas pib, cov hlau electrode yog qhov tseem ceeb. Coated nrog cov ntaub ntawv xws li tooj dag lossis zinc, nws tiv thaiv cov kev cuam tshuam ntawm qhov kub thiab txias. Tswj los ntawm lub computer, nws ua kom raug txiav nrog tsawg distortion thiab siab precision.

Tolerances rau Hlau EDM

Hlau txiav yog cov txheej txheem tsim khoom muaj tseeb tshaj plaws muaj. Yog li, nruj tolerances tsis tawm ntawm qhov dog dig rau nws. Qhov kev kam rau siab tiag tiag yog nyob ntawm ntau yam xws li qhov project intricacies, machining peev xwm, thiab tus neeg teb xov tooj cov kev txawj.

Txawm li cas los xij, tus qauv thiab kev kam lees txais yog ib qho kev lag luam benchmark uas ntau tus neeg tsim khoom ua raws.

Standard Tolerance thiab Fine Tolerance

Standard Tolerance

Linear Tolerances: Feem ntau ntawm ± 0.005 txog ± 0.001 ntiv tes (0.127 txog 0.0254 mm), qhia txog qhov sib txawv ntawm qhov tso cai rau cov yam ntxwv xws li qhov, qhov, lossis cov profiles.

Qhov Txoj kab uas hla Tolerances: Feem ntau ntawm ± 0.0005 mus rau ± 0.001 ntiv tes (0.0127 txog 0.0254 mm), kom ntseeg tau tias lub qhov machined nyob rau hauv txoj kab uas hla.

Siab Zoo

Linear Tolerances: Ua tiav qhov tseeb ntawm qib micron, feem ntau yog li ntawm ± 0.0002 txog ± 0.0001 ntiv tes (0.0051 txog 0.00254 mm), qhov tseem ceeb rau cov ntawv thov xav tau qhov tseeb tshaj plaws.

Qhov Txoj kab uas hla Tolerances: Ntau yam ntawm ± 0.0001 txog ± 0.00005 nti (0.00254 txog 0.00127 mm), qhia txog Hlau EDM qhov tshwj xeeb precision.

Cov yam ntxwv cuam tshuam rau kev kam rau siab hauv Hlau EDM

Hlau EDM yog nto moo rau nws micron-theem precision, ua rau nws zoo tagnrho rau intricate daim ntaub ntawv. Txawm li cas los xij, nws qhov kev ua tau zoo tsis raug kho thiab hinges ntawm ntau yam:

•Machine Stability: Lub tshuab ruaj khov ua kom zoo dua qhov kev txiav txim siab.

• Hlau Zoo thiab txoj kab uas hla: Nws purity, txoj kab uas hla, thiab hluav taws xob zoo cuam tshuam cov txheej txheem machining. Cov txiaj ntsig zoo yuav tsum muaj qhov sib npaug ntawm cov hlau zoo thiab txoj kab uas hla.

• Cov Khoom Siv Ua Haujlwm: Txawm tias qee cov khoom siv tau yooj yim rau cov tshuab, cov khoom xaiv yuav tsum ua raws li daim ntawv thov xav tau.

•Flush Conditions: Cov dej ntws ntawm cov dielectric nruab nrab, cuam tshuam qhov zoo ntawm cov txheej txheem machining, pab tshem tawm cov khoom, cov hluav taws xob zoo ib yam, thiab ua kom muaj cua sov zoo.

•Machine Calibration thiab Maintenance: Lub tshuab muaj peev xwm yog qhov tseem ceeb. Cov tshuab zoo tshaj plaws nrog cov neeg ua haujlwm tau zoo yog qhov tseem ceeb rau kev ua tiav qhov kev zam zoo tshaj plaws.

•Thermal Stability: Txhawm rau kom paub qhov tseeb ntawm Hlau EDM, tswj hluav taws xob arcs yog qhov tseem ceeb. Thermal instabilities tuaj yeem cuam tshuam qhov tseeb, hais txog qhov tseem ceeb ntawm cov xwm txheej zoo ib yam.

Cov ntaub ntawv tsim nyog tshaj plaws rau hlau txiav

Ferrous hlau

Stainless hlau

Nws combines durability nrog zoo heev hluav taws xob conductivity. Nws lub peev xwm los tiv thaiv corrosion ua rau nws cov khoom nrhiav-tom qab hauv ntau qhov kev lag luam. Nyob rau hauv cov ntsiab lus ntawm machining, nws compatibility nrog meej thiab ncauj lus kom ntxaws designs stands.

Cov cuab yeej hlau

Renowned rau nws cov yam ntxwv hardened, cov cuab yeej steel yog cov caj qaum ntawm ntau cov cuab yeej hnyav thiab qhov tseeb. Nws lub hauv paus toughness, thaum ua ke nrog nws cov khoom siv hluav taws xob, ua rau nws yog tus neeg sib tw tseem ceeb rau kev nthuav dav zoo nkauj thiab ntev ntev sharpness.

Carbon Steel

Ib tug ntau yam neeg uas ua ntawv nyob rau hauv cov hlau domains, carbon steel, tab sis tsawg machinable tshaj nws counterparts, yuav ua tau raws li zoo raws li txoj cai electrode xaiv thiab kev ua hauj lwm tsis. Nws cov nqi pheej yig ua ke nrog nws cov kev ua tau zoo ua rau nws yog ib qho tseem ceeb hauv ntau qhov kev lag luam.

Hlau alloy

Kev sib xyaw ua ke ntawm cov ntsiab lus, alloy steel qhov kev ua tau zoo yog tapestry ntawm nws cov khoom. Nyob ntawm nws qhov sib xyaw tshwj xeeb, nws tuaj yeem muab lub zog, durability, thiab machinability, ua rau nws xaiv dynamic rau ntau yam kev siv.

Cov hlau tsis muaj hlau

Titanium

Feem ntau hu ua 'qhov chaw hnub nyoog hlau', titanium robustness thiab siab melting point ua teeb meem hauv cov pa machining. Txawm li cas los xij, thaum chiseled nrog cov cuab yeej precision, nws nthuav tawm cov qauv tsim uas muaj ob qho tib si sib txawv thiab muaj zog, ua rau nws nyiam rau kev lag luam aerospace thiab kev kho mob.

Aluminium

Lub darling ntawm lub teeb yuag hlau, aluminium yog ua kev zoo siab rau nws splendid hluav taws xob conductivity thiab malleability. Nws tsis tsuas yog muab kev yooj yim ntawm machining tab sis kuj cog lus lub zog tsis muaj lub nra hnyav, ua rau nws tseem ceeb hauv kev lag luam los ntawm kev thauj mus los rau kev ntim khoom.

Tooj

Ib tug neeg xyuas pib par zoo, tooj liab yog nyob rau hauv lub plawv ntawm ntau yam hluav taws xob thiab hluav taws xob marvels. Nws lub ntuj reddish-txiv kab ntxwv hue ua ke nrog nws lub peev xwm los ua kom zoo nkauj rau hauv cov ncauj lus kom ntxaws ua rau nws indispensable nyob rau hauv txhua yam ntawm electronics mus rau cov hniav kos duab.

Brass thiab Bronze

Cov alloys, resplendent nyob rau hauv lawv cov golden tones, tsis yog hais txog kev zoo nkauj. Lawv cov khoom siv hluav taws xob qhuas tau ua rau lawv mus rau cov khoom siv rau cov khoom siv uas qhov tseeb ua tau raws li kev zoo nkauj, xws li hauv cov hniav nyiaj hniav kub ornate los yog cov khoom siv hluav taws xob zoo.

Cov ntawv thov tseem ceeb ntawm Hlau EDM hauv Kev Tsim Kho Niaj Hnub No

Hlau EDM machining yog tau txais traction vim nws versatility nyob rau hauv tuav ntau yam ntaub ntawv thiab nws muaj peev xwm mus cuag cov ntsiab lus meej thiab nruj tolerances, ua rau nws tseem ceeb nyob rau hauv niaj hnub manufacturing. Nov yog peb daim ntawv thov tseem ceeb:

Precision Parts Manufacturing

Qhov kev xaiv zoo tshaj plaws rau kev tsim cov khoom siv high-precision nrog nruj tolerances. Nws ua tau zoo hauv kev tsim cov duab, cov ntsiab lus zoo, thiab cov yam ntxwv me me hauv ntau yam ntaub ntawv.

Kev lag luam xws li aerospace, kev kho mob, tsheb, thiab hluav taws xob cia siab rau Hlau EDM los tsim cov khoom tseem ceeb xws li iav, nozzles, connectors, thiab pwm intricate.

Tool thiab Tuag Production

Hlau EDM yog cov cuab yeej siv hauv kev tsim pwm, tuag, thiab cov cuab yeej tshwj xeeb, ua rau cov txheej txheem los ntawm kev txhaj tshuaj molding mus rau stamping. Txoj kev muaj txiaj ntsig hauv kev txhawb nqa qhov ntev thiab kos cov kaum ntse ntse kom paub meej qhov zoo thiab sib xws hauv cov khoom loj.

Kev tsim qauv qauv

Rau nrawm thiab meej prototyping, engineers thiab innovators gravitate rau Hlau EDM. Qhov no expedites tsim validation thiab nruj xeem theem.

Prototypes chiseled ntawm Hlau EDM ze ze tsom iav qhov kawg cov khoom, txhawb nqa nws qhov tseem ceeb hauv cov khoom lag luam evolution.

Muab nws lub zog nyob rau hauv cov cheeb tsam tseem ceeb no, Wire EDM qhov tseeb thiab muaj peev xwm muaj tseeb tau siv dav dav thoob plaws ntau qhov kev lag luam.

•Kev tsim khoom siv kho mob

•Electronics thiab Micro-components

•Aerospace thiab Aviation

• Nyiaj kub thiab Watchmaking

• Automotive Kev Lag Luam

•Energy Sector

• Pwm thiab Tuag Kho

Post lub sij hawm: Dec-12-2023