Ib qho kev piav qhia ntawm CNC machining, feem ntau lub sijhawm, suav nrog kev ua haujlwm nrog cov hlau ua haujlwm. Txawm li cas los xij, tsis tsuas yog CNC machining dav siv rau cov yas, tab sis yas CNC machining kuj yog ib qho ntawm cov txheej txheem machining ntau hauv ntau qhov kev lag luam.

Kev lees txais ntawm cov yas machining raws li kev tsim khoom yog vim muaj ntau yam ntawm cov khoom siv yas CNC muaj. Tsis tas li ntawd, nrog kev qhia txog kev tswj xyuas cov lej hauv computer, cov txheej txheem ua kom raug, nrawm dua, thiab tsim nyog rau kev ua cov khoom nrog nruj kam rau ua. Koj paub ntau npaum li cas txog yas CNC machining? Kab lus no tham txog cov ntaub ntawv sib xws nrog cov txheej txheem, cov txheej txheem muaj, thiab lwm yam uas tuaj yeem pab koj qhov project.

Plastics rau CNC Machining

Ntau lub tshuab machinable plastics yog tsim rau kev tsim khoom thiab cov khoom lag luam ntau qhov chaw tsim khoom. Lawv siv nyob ntawm lawv cov khoom, nrog rau qee cov khoom siv yas, xws li nylon, muaj cov khoom siv zoo heev uas tso cai rau lawv hloov cov hlau. Hauv qab no yog cov khoom siv ntau tshaj plaws rau kev cai yas machining:

ABS:

Acrylonitrile Butadiene Styrene, los yog ABS, yog lub teeb yuag CNC cov khoom paub txog nws qhov kev cuam tshuam, lub zog, thiab kev ua haujlwm siab. Txawm hais tias nws boasts zoo txhua yam khoom, nws tsis tshua muaj tshuaj stability yog pom tseeb nyob rau hauv nws susceptibility rau roj, cawv, thiab lwm yam tshuaj solvents. Tsis tas li ntawd, lub thermal stability ntawm ntshiab ABS (xws li, ABS tsis muaj additives) yog tsawg, raws li cov yas polymer yuav hlawv txawm tias tom qab tshem tawm cov nplaim taws.

Pros

Nws yog lub teeb yuag yam tsis poob nws lub zog txhua yam.

Cov yas polymer yog cov machinable heev, ua rau nws nrov heev sai prototyping khoom.

ABS muaj cov ntsiab lus melting tsawg tsim nyog (qhov no yog qhov tseem ceeb rau lwm cov txheej txheem sai sai xws li 3D luam ntawv thiab txhaj tshuaj molding).

Nws muaj lub zog tensile siab.

ABS muaj lub zog ruaj khov, uas txhais tau tias lub neej ntev dua.

Nws yog pheej yig.

Cons

Nws tso cov pa yas kub thaum raug cua sov.

Koj xav tau qhov cua kom zoo los tiv thaiv kev tsim cov pa roj.

Nws muaj qhov qis melting point uas tuaj yeem ua rau deformation los ntawm cov cua sov tsim los ntawm CNC tshuab.

Daim ntawv thov

ABS yog cov khoom siv hluav taws xob nrov heev uas siv los ntawm ntau qhov kev pabcuam sai sai hauv kev tsim cov khoom vim nws cov khoom zoo heev thiab pheej yig. Nws muaj feem xyuam rau hauv kev lag luam hluav taws xob thiab tsheb hauv kev tsim cov khoom xws li lub kaus mom keyboard, cov khoom siv hluav taws xob, thiab cov khoom siv hauv tsheb dashboard.

Nylon

Nylon los yog polyamide yog cov yas tsis tshua muaj kev sib txhuam polymer nrog kev cuam tshuam, tshuaj lom neeg, thiab kev puas tsuaj. Nws cov khoom siv zoo heev, xws li lub zog (76mPa), durability, thiab hardness (116R), ua rau nws zoo heev rau CNC machining thiab ntxiv txhim kho nws daim ntawv thov nyob rau hauv lub tsheb thiab kho mob kev lag luam.

Pros

Zoo heev mechanical zog.

Nws muaj lub zog tensile siab.

Nqi-zoo.

Nws yog lub teeb yuag polymer.

Nws yog kub thiab tshuaj resistant.

Cons

Nws muaj qhov tsis tshua muaj kev ruaj ntseg.

Nylon tuaj yeem nqus tau yooj yim.

Nws yog cov muaj zog mineral acids.

Daim ntawv thov

Nylon yog ib qho kev ua haujlwm siab zoo thermoplastic siv tau rau kev tsim qauv thiab tsim cov khoom tiag hauv kev kho mob thiab kev lag luam tsheb. Cov khoom tsim los ntawm cov khoom siv CNC muaj xws li bearings, washers, thiab hlab.

Acrylic

Acrylic los yog PMMA (Poly Methyl Methacrylate) yog nrov hauv cov yas CNC machining vim nws cov khoom kho qhov muag. Cov yas polymer yog translucence thiab khawb resistant, yog li nws cov ntawv thov hauv kev lag luam uas xav tau cov khoom zoo li no. Tsis tas li ntawd, nws muaj cov khoom siv zoo heev, pom tseeb hauv nws qhov toughness thiab cuam tshuam tsis kam. Nrog nws cov pheej yig, acrylic CNC machining tau dhau los ua lwm txoj hauv kev yas polymers xws li polycarbonate thiab iav.

Pros

Nws yog lub teeb yuag.

Acrylic yog tshuaj lom neeg thiab UV resistant.

Nws muaj siab machinability.

Acrylic muaj tshuaj tiv thaiv siab.

Cons

Nws tsis yog qhov uas tiv taus tshav kub, cuam tshuam, thiab puas.

Nws tuaj yeem tawg hauv qhov hnyav.

Nws tsis tiv taus chlorinated / aromatic organic tshuaj.

Daim ntawv thov

Acrylic yog siv tau los hloov cov ntaub ntawv xws li polycarbonate thiab iav. Yog li ntawd, nws muaj feem xyuam rau hauv kev lag luam tsheb rau kev ua cov kav dej thiab lub tsheb qhia lub teeb npog thiab lwm yam lag luam rau kev ua cov hnub ci vaj huam sib luag, tsev cog khoom, thiab lwm yam.

POM

POM los yog Delrin (lub npe lag luam) yog cov khoom siv yas CNC zoo heev uas tau xaiv los ntawm ntau cov kev pabcuam CNC machining rau nws lub zog siab thiab ua haujlwm rau cov cua sov, tshuaj, thiab hnav / kua muag. Muaj ntau qib ntawm Delrin, tab sis feem ntau kev lag luam cia siab rau Delrin 150 thiab 570 vim tias lawv muaj qhov ruaj khov.

Pros

Lawv yog cov machinable tshaj plaws ntawm tag nrho cov ntaub ntawv yas CNC.

Lawv muaj cov tshuaj tiv thaiv zoo heev.

Lawv muaj kev ruaj ntseg siab.

Nws muaj lub zog tensile siab thiab durability, ua kom lub neej ntev dua.

Cons

Nws muaj qhov tsis zoo rau cov acids.

Daim ntawv thov

POM pom nws daim ntawv thov thoob plaws ntau yam kev lag luam. Piv txwv li, nyob rau hauv lub automotive sector, nws yog siv los tsim cov khoom siv lub rooj zaum. Kev lag luam khoom siv kho mob siv nws los tsim cov cwj mem insulin, thaum cov neeg siv khoom lag luam siv POM los tsim cov luam yeeb hluav taws xob thiab cov ntsuas dej.

HDPE

High-density polyethylene yas yog cov thermoplastic uas muaj zog tiv thaiv kev ntxhov siab thiab corrosive tshuaj. Nws muaj cov khoom siv zoo heev xws li lub zog tensile (4000PSI) thiab hardness (R65) dua li nws cov khoom, LDPE hloov nws hauv cov ntawv thov nrog cov kev xav tau.

Pros

Nws yog ib qho yooj yim machinable yas.

Nws tiv taus kev ntxhov siab thiab tshuaj lom neeg.

Nws muaj cov khoom siv kho tshuab zoo heev.

ABS muaj lub zog ruaj khov, uas txhais tau tias lub neej ntev dua.

Cons

Nws muaj qhov tsis zoo UV tsis kam.

Daim ntawv thov

HDPE Nws muaj ntau yam kev siv, suav nrog kev tsim qauv, tsim lub zog, bearings, ntim, hluav taws xob rwb thaiv tsev, thiab khoom siv kho mob. Nws yog qhov zoo tshaj plaws rau prototyping vim nws tuaj yeem ua tau sai thiab yooj yim, thiab nws tus nqi qis ua rau nws zoo rau kev tsim ntau yam iterations. Tsis tas li ntawd, nws yog ib qho khoom siv zoo rau cov iav vim nws cov coefficient tsis tshua muaj kev sib txhuam thiab kev hnav tsis kam, thiab rau cov bearings, vim nws tus kheej lubricating thiab tshuaj tiv thaiv.

LDPE

LDPE yog ib qho tawv, yoog raws cov yas polymer nrog cov tshuaj lom neeg zoo thiab tsis kub. Nws yog dav siv nyob rau hauv kev kho mob ib feem raug kev lag luam rau ua prosthetics thiab orthotics.

Pros

Nws yog tawv thiab hloov tau.

Nws yog heev corrosion-resistant.

Nws yog ib qho yooj yim rau kev sib khi siv cov txheej txheem cua sov xws li vuam.

Cons

Nws yog tsis tsim nyog rau qhov chaw uas yuav tsum tau high-temperature kuj.

Nws muaj qhov tsis tshua muaj zog thiab cov qauv tsim muaj zog.

Daim ntawv thov

LDPE feem ntau yog siv los tsim cov kev cai iav thiab cov khoom siv kho tshuab, cov khoom siv hluav taws xob xws li insulators thiab vaj tse rau cov khoom siv hluav taws xob, thiab cov khoom uas muaj polished lossis glossy. Dab tsi ntxiv. nws tsis tshua muaj coefficient ntawm kev sib txhuam, siab rwb thaiv tsev tsis kam, thiab durability ua rau nws zoo tagnrho cov ntaub ntawv rau high-kev ua tau zoo daim ntaub ntawv.

Polycarbonate

PC yog ib qho tawv tab sis hnyav yas polymer nrog kub retardant thiab hluav taws xob insulating zog. Zoo li acrylic, nws tuaj yeem hloov iav vim nws qhov pom tseeb.

Pros

Nws muaj txiaj ntsig zoo dua li feem ntau engineering thermoplastics.

Nws yog ib txwm pob tshab thiab muaj peev xwm kis tau lub teeb.

Nws siv xim zoo heev.

Nws muaj lub zog tensile siab thiab durability.

PC yog resistant rau diluted acids, roj, thiab roj.

Cons

Nws degrades tom qab lub sij hawm raug dej ntau tshaj 60 ° C.

Nws yog raug rau hydrocarbon hnav.

Nws yuav daj thaum lub sij hawm tom qab lub sij hawm ntev raug rau UV rays.

Daim ntawv thov

Raws li nws cov khoom siv lub teeb, polycarbonate tuaj yeem hloov cov khoom iav. Li no, nws yog siv los ua cov tsom iav tsom iav thiab CDs / DVDs. Tsis tas li ntawd, nws yog qhov tsim nyog los ua cov khoom siv phais mob thiab cov khoom siv hluav taws xob.

Yas CNC Machining Methods

CNC yas ib feem machining yuav siv lub tshuab computer tswj kom tshem tawm ib feem ntawm cov yas polymer los ua cov khoom xav tau. Cov txheej txheem tsim tawm tuaj yeem tsim ntau yam ntawm cov khoom nrog nruj kam rau ua, sib xws, thiab raug siv cov hauv qab no.

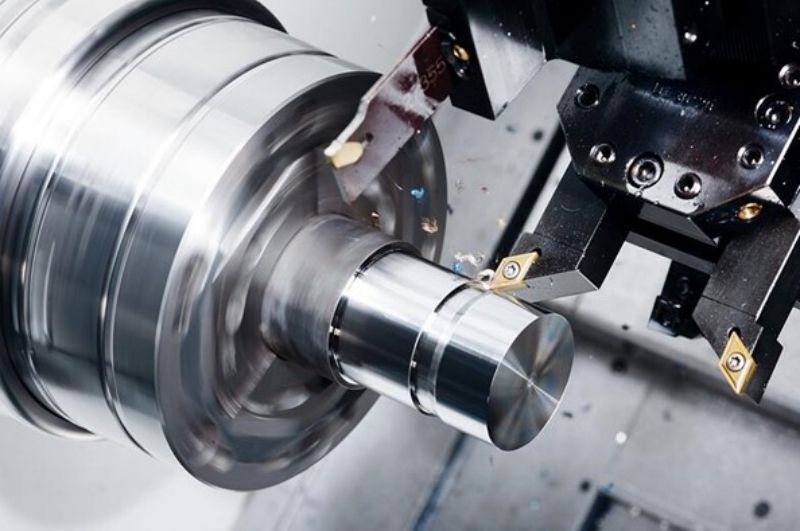

CNC tig

CNC tig yog cov txheej txheem machining uas suav nrog tuav lub workpiece ntawm lub tshuab dhos thiab tig nws tawm tsam cov cuab yeej txiav los ntawm kev tig los yog tig. Kuj tseem muaj ntau hom CNC tig, suav nrog:

Ncaj lossis cylindrical CNC tig yog tsim rau kev txiav loj.

Taper CNC tig yog tsim rau tsim qhov chaw nrog lub khob zoo li cov duab.

Muaj ntau cov lus qhia uas koj tuaj yeem siv rau hauv cov yas CNC tig, suav nrog:

Xyuas kom cov npoo txiav muaj qhov tsis zoo rov qab rake kom txo qis qis.

Txiav ntug yuav tsum muaj lub kaum sab xis zoo.

Polish lub workpiece nto kom zoo dua nto tiav thiab txo cov khoom tsim.

Txo tus nqi pub rau kev txhim kho qhov tseeb ntawm qhov kawg txiav (siv tus nqi pub ntawm 0.015 IPR rau kev txiav ntxhib thiab 0.005 IPR rau kev txiav meej).

Tailor lub clearance, sab, thiab rake kaum rau cov khoom yas.

CNC Milling tshuab

CNC milling suav nrog kev siv lub tshuab milling kom tshem tawm cov khoom ntawm lub workpiece kom tau qhov yuav tsum tau ua. Muaj ntau hom CNC milling tshuab muab faib ua 3-axis mills thiab multi-axis mills.

Ntawm qhov tod tes, 3-axis CNC milling tshuab tuaj yeem txav mus rau hauv peb txoj kab ncaj nraim (sab laug mus rau sab xis, rov qab thiab tawm, nce thiab nqis). Yog li ntawd, nws yog qhov zoo rau kev tsim cov khoom nrog cov qauv yooj yim. Ntawm qhov tod tes, multi-axis mills tuaj yeem txav mus rau ntau tshaj peb axes. Yog li ntawd, nws yog tsim rau CNC machining yas qhov chaw nrog nyuaj geometry.

Muaj ntau cov lus qhia uas koj tuaj yeem siv hauv cov yas CNC milling, suav nrog:

Tshuab lub thermoplastic reinforced nrog carbon lossis iav nrog cov cuab yeej carbon.

Ua kom lub spindle ceev los ntawm kev siv clamps.

Txo kev ntxhov siab los ntawm kev tsim cov kab sib npaug sab hauv.

Txias ncaj qha rau ntawm lub router kom disperse cua sov.

Xaiv qhov kev sib hloov ceev.

Debur yas qhov chaw tom qab milling los txhim kho qhov chaw tiav.

CNC Drilling

Yas CNC drilling yuav tsim ib lub qhov nyob rau hauv ib tug yas workpiece siv ib tug laum mounted nrog ib tug laum ntsis. Lub laum me me qhov loj thiab cov duab txiav txim siab lub qhov loj. Tsis tas li ntawd, nws tseem ua lub luag haujlwm hauv kev khiav tawm ntawm cov nti. Cov hom kev xyaum xovxwm koj tuaj yeem siv tau suav nrog lub rooj zaum, upright, thiab radial.

Muaj ntau cov lus qhia uas koj tuaj yeem siv hauv cov yas CNC drilling, suav nrog:

Xyuas kom koj siv cov cuab yeej CNC ntse kom tsis txhob muaj kev ntxhov siab rau cov khoom siv yas.

Siv lub laum zoo. Piv txwv li, 90 txog 118 ° laum me ntsis nrog lub kaum sab xis ntawm 9 txog 15 ° yog haum rau feem ntau cov thermoplastic (rau acrylic, siv 0 ° rake).

Xyuas kom ib qho yooj yim nti ejection los ntawm kev xaiv qhov zoo xyaum me ntsis.

Siv lub tshuab cua txias kom txo tau cov khoom tsim tawm ntau dua thaum lub sijhawm machining.

Txhawm rau tshem tawm CNC laum yam tsis muaj kev puas tsuaj, xyuas kom meej qhov tob drilling tsawg dua peb lossis plaub zaug. lub laum txoj kab uas hla. Tsis tas li ntawd, txo tus nqi noj thaum lub laum yuav luag tawm ntawm cov khoom.

Alternatives rau Plastic Machining

Ib cag ntawm CNC yas ib feem machining, lwm cov txheej txheem prototyping ceev tuaj yeem ua lwm txoj hauv kev. Cov feem ntau muaj xws li:

Txhaj Molding

Qhov no yog cov txheej txheem tsim khoom nrov rau kev ua haujlwm nrog cov khoom siv yas. Kev txhaj tshuaj molding yuav tsim pwm los ntawm txhuas los yog hlau nyob ntawm seb yam xws li lub neej ntev. Tom qab ntawd, molten yas yog txhaj rau hauv pwm kab noj hniav, txias, thiab ua cov duab uas xav tau.

Yas txhaj molding yog tsim rau ob qho tib si prototyping thiab kev tsim cov khoom tiag. Ib cag ntawm qhov ntawd, nws yog ib txoj hauv kev zoo tsim nyog rau qhov chaw nrog cov qauv tsim thiab yooj yim. Tsis tas li ntawd, kev txhaj tshuaj molded qhov tsis tas yuav tsum tau ua haujlwm ntxiv lossis kho qhov chaw.

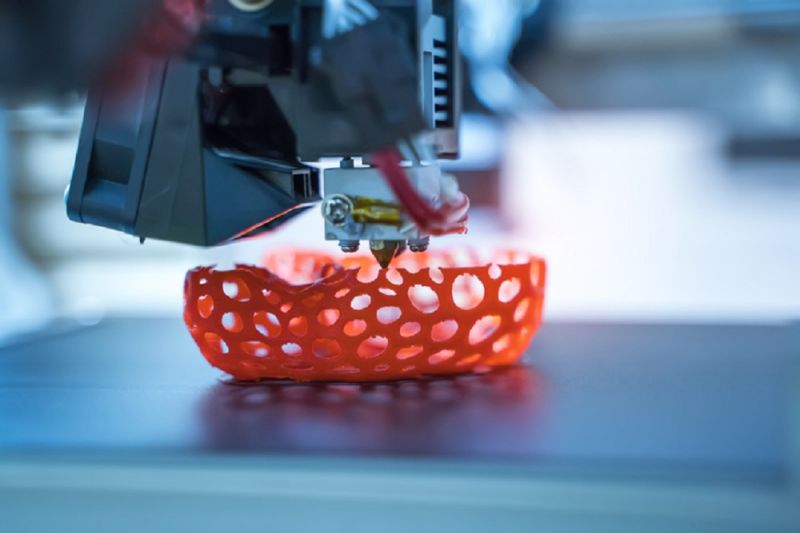

3D luam ntawv

3D luam ntawv yog cov qauv siv feem ntau siv hauv kev lag luam me. Cov txheej txheem tsim khoom ntxiv yog cov cuab yeej ua qauv sai uas suav nrog cov thev naus laus zis xws li Stereolithography (SLA), Fused Deposition Modeling (FDM), thiab Xaiv Laser Sintering (SLS) siv rau kev ua haujlwm ntawm cov thermoplastics xws li nylon, PLA, ABS, thiab ULTEM.

Txhua lub thev naus laus zis suav nrog tsim cov qauv 3D digital thiab tsim cov txheej txheem xav tau los ntawm txheej. Qhov no zoo li yas CNC machining, txawm hais tias nws cuam tshuam cov khoom siv tsawg dua, tsis zoo li yav tas los. Tsis tas li ntawd, nws tshem tawm qhov xav tau ntawm cov cuab yeej thiab tsim nyog rau kev ua cov khoom nrog cov qauv tsim.

Nqus Casting

Nqus casting los yog polyurethane / urethane casting muaj silicon pwm thiab resins los ua ib daim qauv ntawm tus tswv. Cov txheej txheem prototyping sai yog tsim los tsim cov yas nrog cov khoom zoo. Tsis tas li ntawd, cov ntawv theej yog siv tau hauv kev pom cov tswv yim lossis daws teeb meem tsim qhov tsis zoo.

Muaj kev siv ntawm yas CNC Machining

Yas CNC machining yog dav siv los ntawm cov txiaj ntsig xws li qhov tseeb, qhov tseeb, thiab kev ua siab ntev. Common industrial applications ntawm cov txheej txheem muaj xws li:

Kev lag luam kho mob

CNC yas machining yog tam sim no muaj feem xyuam rau hauv kev tsim kho mob machined qhov chaw xws li cov ceg tawv thiab lub siab dag. Nws cov qib siab ntawm qhov raug thiab rov ua dua tso cai rau nws kom ua tau raws li cov qauv kev nyab xeeb nruj uas xav tau los ntawm kev lag luam. Tsis tas li ntawd, muaj ntau yam khoom siv xaiv, thiab nws tsim cov duab nyuaj.

Automotive Cheebtsam

Ob lub tsheb tsim thiab engineers siv Plastic CNC machining los ua cov khoom siv tsheb tiag tiag thiab cov qauv tsim. Yas yog siv dav hauv kev lag luam hauv kev ua cov khoom siv cnc yas xws li dashboards vim nws lub teeb yuag, uas txo cov roj noj. Tsis tas li ntawd, yas yog resistant rau corrosion thiab hnav, uas feem ntau automotive Cheebtsam muaj kev paub. Tsis tas li ntawd, yas yog moldable rau hauv complex duab yooj yim.

Aerospace Qhov Chaw

Aerospace ib feem ntawm kev tsim khoom yuav tsum muaj txoj kev tsim khoom uas muaj qhov ua tau zoo thiab nruj kam rau ua. Raws li qhov tshwm sim, kev lag luam xaiv rau CNC machining hauv kev tsim, sim, thiab tsim cov khoom siv aerospace sib txawv. Cov ntaub ntawv yas siv tau vim lawv qhov tsim nyog rau cov duab nyuaj, lub zog, lub teeb yuag thiab cov tshuaj muaj zog, thiab kub tsis kam.

Kev lag luam hluav taws xob

Kev lag luam hluav taws xob kuj nyiam CNC yas machining vim nws qhov siab precision thiab rov ua dua. Tam sim no, cov txheej txheem yog siv los ua CNC-machined yas cov khoom siv hluav taws xob xws li cov ntaub ntawv xov hlau, cov keyboards, thiab cov ntxaij vab tshaus LCD.

Thaum xaiv Yas CNC Machining

Xaiv los ntawm ntau cov txheej txheem tsim khoom yas tau tham saum toj no tuaj yeem nyuaj. Yog li ntawd, hauv qab no yog ob peb qhov kev txiav txim siab uas tuaj yeem pab koj txiav txim siab yog tias cov yas CNC machining yog cov txheej txheem zoo dua rau koj qhov project:

Yog Yas Qauv Tsim nrog Tight Tolerance

CNC yas machining yog txoj kev zoo dua rau kev ua cov khoom nrog cov qauv tsim uas yuav tsum tau ua kom nruj nruj. Lub tshuab CNC milling ib txwm tuaj yeem ua tiav qhov siab ntev li ntawm 4 μm.

Yog hais tias Yas Prototype Yuav Tsum Tau Zoo Nto tiav

CNC tshuab muaj qhov zoo tshaj plaws nto tiav ua kom haum yog tias koj qhov project tsis xav tau cov txheej txheem saum npoo ntxiv. Qhov no tsis zoo li 3D luam ntawv, uas tawm txheej txheej thaum luam ntawv.

Yog Yas Qauv Xav Tau Cov Khoom Tshwj Xeeb

Yas CNC machining tuaj yeem siv los tsim cov khoom los ntawm ntau cov ntaub ntawv yas, nrog rau cov khoom tshwj xeeb xws li kub-kub tsis kam, siab zog, los yog tshuaj lom neeg muaj zog. Qhov no ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev tsim cov qauv nrog cov kev cai tshwj xeeb.

Yog tias koj cov khoom nyob rau hauv kev sim theem

CNC machining cia siab rau 3D qauv, uas yooj yim hloov. Txij li thaum lub sijhawm xeem yuav tsum tau hloov kho tas li, CNC machining tso cai rau cov neeg tsim qauv thiab cov chaw tsim khoom los tsim cov qauv yas ua haujlwm los kuaj thiab daws teeb meem tsim qhov tsis zoo.

· Yog tias koj xav tau kev xaiv nyiaj txiag

Zoo li lwm yam kev tsim khoom, yas CNC machining yog tsim los ua cov khoom siv tau zoo. Cov yas tsis tshua muaj nqi ntau dua li cov hlau thiab lwm yam khoom siv, xws li cov khoom sib xyaw. Tsis tas li ntawd, kev tswj xyuas tus lej hauv computer yog qhov tseeb dua, thiab cov txheej txheem tsim nyog rau kev tsim qauv.

Xaus

CNC yas machining yog cov txheej txheem kev lag luam dav dav vim nws qhov tseeb, ceev, thiab tsim nyog rau kev ua cov khoom nrog nruj kam rau ua. Kab lus no tham txog cov khoom sib txawv ntawm CNC machining cov txheej txheem, muaj cov txheej txheem, thiab lwm yam uas tuaj yeem pab koj qhov project.

Xaiv cov txheej txheem machining txoj cai tuaj yeem nyuaj heev, xav tau koj mus rau outsource rau lub chaw muab kev pabcuam yas CNC. Ntawm GuanSheng peb muab cov kev cai yas CNC machining cov kev pab cuam thiab tuaj yeem pab koj ua qhov sib txawv rau kev tsim qauv lossis siv sijhawm tiag tiag raws li koj xav tau.

Peb muaj ntau yam ntaub ntawv yas haum rau CNC machining nrog ib tug nruj thiab streamlined txheej txheem xaiv. Tsis tas li ntawd, peb pab neeg ua haujlwm engineering tuaj yeem muab cov lus qhia xaiv cov khoom siv thiab cov lus pom zoo tsim. Upload koj tus qauv tsim hnub no thiab tau txais cov lus qhia tam sim thiab kev tshuaj xyuas DfM dawb ntawm tus nqi sib tw.

Post lub sij hawm: Nov-13-2023