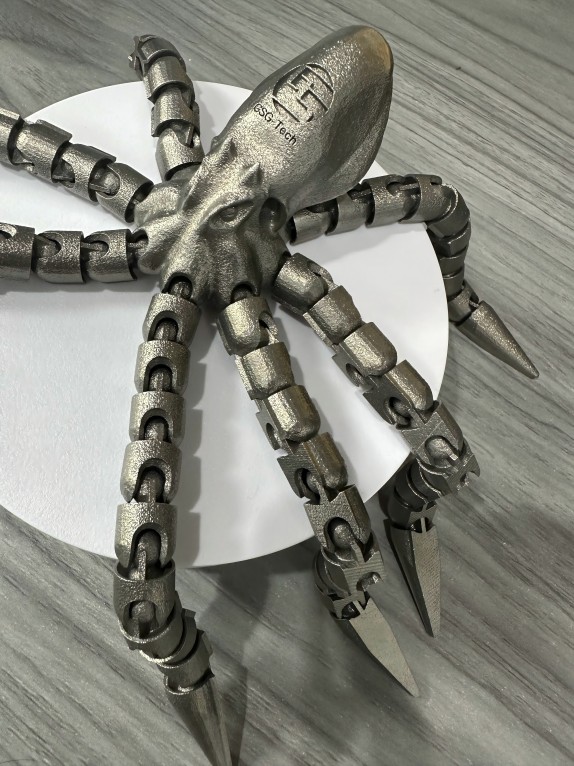

Tsis ntev los no, peb tau ua qauv qhia txog hlau3D luam ntawv, thiab peb ua tiav nws zoo heev, yog li cas yog hlau3D luam ntawv? Dab tsi yog nws qhov zoo thiab qhov tsis zoo?

Hlau 3D luam ntawv yog ib qho kev tsim khoom siv ntxiv uas tsim cov khoom peb sab los ntawm kev ntxiv cov ntaub ntawv hlau los ntawm txheej. Nov yog cov lus qhia ntxaws ntxaws rau hlau 3D luam ntawv:

Technical txoj cai

Selective laser sintering (SLS) : Kev siv lub zog siab laser beams los xaiv yaj thiab sinter hlau hmoov, cua sov cov hmoov khoom kom sov me ntsis hauv qab nws melting point, kom metallurgical bonds ntawm hmoov hais, yog li tsim cov khoom txheej los ntawm txheej. Nyob rau hauv cov txheej txheem luam ntawv, ib txheej ntawm cov hmoov hlau tsis sib xws yog thawj zaug tso rau ntawm lub tshuab luam ntawv, thiab tom qab ntawd lub laser beam scans cov hmoov raws li cov duab ntoo khaub lig ntawm cov khoom, kom cov hmoov scanned melts thiab solidifies ua ke, tom qab ua tiav ntawm txheej luam ntawv, lub platform poob ib qho kev ncua deb, thiab tom qab ntawd kis cov hmoov txheej tshiab, rov ua cov txheej txheem saum toj no kom txog thaum tag nrho cov khoom luam tawm.

Selective Laser Melting (SLM) : Zoo ib yam li SLS, tab sis nrog lub zog laser ntau dua, cov hmoov hlau tuaj yeem ua tiav los ua cov qauv denser, qhov ntom ntom dua thiab cov khoom siv kho tshuab zoo dua tuaj yeem tau txais, thiab lub zog thiab qhov tseeb ntawm cov hlau luam ntawv yog siab dua, nyob ze lossis ntau dua cov khoom tsim los ntawm cov txheej txheem tsim khoom ib txwm muaj. Nws yog tsim rau kev tsim khoom hauv aerospace, khoom siv kho mob thiab lwm yam kev lag luam uas yuav tsum tau muaj kev ua haujlwm siab thiab kev ua haujlwm.

Electron beam melting (EBM): Kev siv cov kab hluav taws xob ua hluav taws xob los ua cov hmoov hlau yaj. Cov hluav taws xob nqaj muaj cov yam ntxwv ntawm lub zog hluav taws xob ceev thiab siab scanning ceev, uas tuaj yeem sai melt hlau hmoov thiab txhim kho kev luam ntawv. Kev luam ntawv hauv ib puag ncig lub tshuab nqus tsev tuaj yeem zam cov tshuaj tiv thaiv ntawm cov ntaub ntawv hlau nrog oxygen thaum lub sijhawm luam ntawv, uas yog tsim rau kev luam ntawv titanium alloy, npib tsib xee-raws li alloy thiab lwm yam hlau cov ntaub ntawv rhiab heev rau cov ntsiab lus oxygen, feem ntau siv hauv aerospace, cov cuab yeej kho mob thiab lwm yam high-end teb.

Cov khoom siv hlau extrusion (ME): Cov khoom siv extrusion raws li kev tsim khoom, los ntawm lub taub hau extrusion kom extrude cov khoom siv hlau nyob rau hauv daim ntawv ntawm txhob lo lo ntxhuav los yog muab tshuaj txhuam, thiab tib lub sij hawm kom sov thiab kho, thiaj li ua tiav txheej los ntawm txheej tsub zuj zuj molding. Piv nrog rau laser melting technology, cov peev txheej yog qis dua, hloov tau yooj yim thiab yooj yim, tshwj xeeb tshaj yog tsim rau kev loj hlob thaum ntxov hauv chaw ua haujlwm thiab ib puag ncig kev lag luam.

Cov khoom siv

Titanium alloy: muaj qhov zoo ntawm lub zog siab, tsis tshua muaj siab, zoo corrosion kuj thiab biocompatibility, dav siv hauv aerospace, khoom siv kho mob, tsheb thiab lwm yam, xws li dav hlau cav hniav, pob qij txha thiab lwm yam kev tsim khoom.

Stainless hlau: muaj kev tiv thaiv corrosion zoo, cov khoom siv kho tshuab thiab kev ua haujlwm, tus nqi qis, yog ib qho ntawm cov khoom siv feem ntau hauv cov hlau 3D luam ntawv, tuaj yeem siv los tsim ntau yam khoom siv, cov cuab yeej, cov cuab yeej kho mob thiab lwm yam.

Aluminium alloy: tsis tshua muaj siab, siab zog, zoo thermal conductivity, haum rau kev tsim khoom nrog siab hnyav, xws li lub tsheb cav lub tog raj kheej thaiv, aerospace structural qhov chaw, thiab lwm yam.

Nickel-raws li alloy: nrog zoo kub kub lub zog, corrosion kuj thiab oxidation tsis kam, nws yog feem ntau siv nyob rau hauv lub tsim ntawm kub Cheebtsam xws li aircraft xyaw thiab roj turbines.

qhov zoo

High degree ntawm kev ywj pheej tsim: Muaj peev xwm ua tiav kev tsim cov duab thiab cov qauv, xws li cov qauv lattice, topologically optimized structures, thiab lwm yam, uas nyuaj los yog tsis yooj yim sua kom ua tiav hauv cov txheej txheem tsim khoom, muab ntau qhov chaw tsim kho tshiab rau cov khoom tsim, thiab tuaj yeem tsim cov khoom sib zog, ua haujlwm siab.

Txo cov naj npawb ntawm cov khoom: ntau qhov chaw tuaj yeem ua ke rau hauv ib qho tag nrho, txo cov kev sib txuas thiab kev sib dhos ntawm cov khoom, txhim kho kev tsim khoom, txo cov nqi, tab sis kuj txhim kho kev ntseeg siab thiab ruaj khov ntawm cov khoom.

Rapid prototyping: Nws tuaj yeem tsim cov qauv ntawm cov khoom lag luam hauv lub sijhawm luv luv, ua kom cov khoom lag luam txhim kho, txo cov nqi tshawb fawb thiab kev tsim kho, thiab pab cov lag luam coj cov khoom lag luam sai dua.

Customized ntau lawm: Raws li tus neeg xav tau kev pab ntawm cov neeg siv khoom, cov khoom tshwj xeeb tuaj yeem tsim kom tau raws li cov kev cai tshwj xeeb ntawm cov neeg siv khoom sib txawv, haum rau kev kho mob cog, hniav nyiaj hniav kub thiab lwm yam kev cai.

Kev txwv

Tsis zoo deg zoo: Qhov saum npoo ntawm cov hlau luam tawm yog qhov siab, thiab kev kho tom qab yuav tsum tau ua, xws li kev sib tsoo, polishing, sandblasting, thiab lwm yam., txhawm rau txhim kho qhov chaw tiav, ua rau cov nqi tsim khoom thiab sijhawm.

Internal defects: tej zaum yuav muaj qhov tsis xws luag xws li pores, unfused hais, thiab tsis tiav fusion thaum lub sij hawm luam ntawv txheej txheem, uas muaj feem xyuam rau cov neeg kho tshuab cov khoom, tshwj xeeb tshaj yog nyob rau hauv daim ntawv thov ntawm siab load thiab cyclic load, nws yog tsim nyog los txo qhov tshwm sim ntawm internal defects los ntawm optimizing cov txheej txheem luam ntawv thiab siv cov txheej txheem tom qab tsim nyog.

Cov kev txwv ntawm cov khoom siv: Txawm hais tias hom hlau 3D luam ntawv cov ntaub ntawv muaj ntau zuj zus, tseem muaj qee yam kev txwv cov khoom siv piv nrog cov qauv tsim, thiab qee cov ntaub ntawv hlau ua tau zoo yog qhov nyuaj rau luam tawm thiab tus nqi siab dua.

Tus nqi teeb meem: Tus nqi ntawm cov khoom siv hlau 3D luam ntawv thiab cov ntaub ntawv yog qhov siab thiab kev luam ntawv qeeb, uas tsis yog tus nqi tsim nyog raws li cov txheej txheem tsim khoom loj, thiab tam sim no feem ntau yog tsim rau cov khoom me me, kev tsim kho thiab thaj chaw nrog cov khoom lag luam siab thiab cov kev xav tau zoo.

Kev tsis yooj yim: Hlau 3D luam ntawv suav nrog cov txheej txheem tsis yooj yim thiab kev tswj hwm txheej txheem, uas yuav tsum muaj cov neeg ua haujlwm tshaj lij thiab kev txhawb nqa, thiab yuav tsum muaj kev ua haujlwm siab thiab kev paub ntawm cov neeg ua haujlwm.

Daim ntawv thov teb

Aerospace: Siv los tsim aero-engine blades, turbine discs, tis qauv, satellite qhov chaw, thiab lwm yam, uas tuaj yeem txo qhov hnyav ntawm qhov chaw, txhim kho roj efficiency, txo cov nqi tsim khoom, thiab xyuas kom muaj kev ua tau zoo thiab kev ntseeg siab ntawm qhov chaw.

Tsheb: Tsim lub tsheb cav lub tog raj kheej thaiv, lub plhaub kis tau tus mob, lub teeb yuag qhov chaw, thiab lwm yam, kom ua tiav cov qauv tsim ntawm lub tsheb, txhim kho roj kev lag luam thiab kev ua haujlwm.

Kev Kho Mob: Kev tsim cov khoom siv kho mob, cov pob qij txha, cov hniav orthotics, cov khoom siv kho mob implantable, thiab lwm yam, raws li tus neeg sib txawv ntawm cov neeg mob customized tsim, txhim kho qhov tsim nyog ntawm cov cuab yeej kho mob thiab kev kho mob.

Kev tsim pwm: Kev tsim cov pwm pwm, tuag casting pwm, thiab lwm yam., ua kom lub voj voog tsim pwm, txo cov nqi, txhim kho qhov tseeb thiab qhov nyuaj ntawm pwm.

Electronics: Tsim cov radiators, plhaub, Circuit Court boards ntawm cov khoom siv hluav taws xob, thiab lwm yam, kom ua tiav kev tsim khoom ntawm cov txheej txheem nyuaj, txhim kho cov kev ua tau zoo thiab cov cua kub dissipation ntawm cov khoom siv hluav taws xob.

Cov hniav nyiaj hniav kub: Raws li tus tsim qauv tsim thiab cov neeg siv khoom xav tau, ntau hom hniav nyiaj hniav kub tshwj xeeb tuaj yeem tsim los txhim kho kev tsim khoom thiab kev tsim khoom tus kheej.

Post lub sij hawm: Nov-22-2024