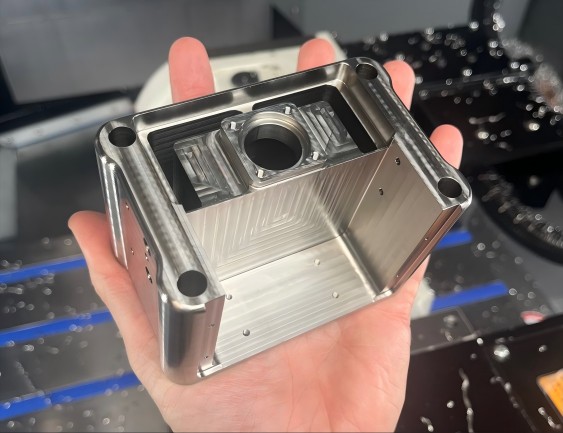

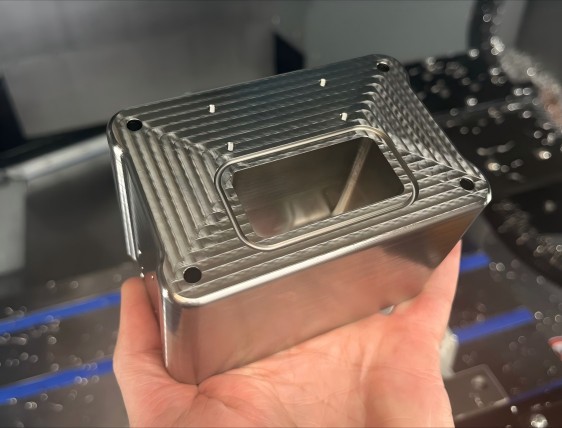

Tsis ntev los no peb tau ua ib pawg ntawm stainless hlau qhov chaw.Qhov qhov yuav tsum tau yog siab heev, uas yuav tsum tau mus txog ± 0.2μm. Cov khoom siv ntawm stainless hlau yog qhov nyuaj. HauvCNC machining ntawm stainless hlau cov ntaub ntawv, Cov kev ntsuas sib xws tuaj yeem raug coj los ntawm kev npaj ua ntej, kev tswj xyuas cov txheej txheem thiab tom qab ua tiav los txhim kho kev ua haujlwm raug. Cov hauv qab no yog cov txheej txheem tshwj xeeb:

Kev npaj ua ntej

• Xaiv cov cuab yeej zoo: raws li cov yam ntxwv ntawm cov khoom siv hlau tsis muaj steel, xws li siab hardness, toughness, thiab lwm yam., xaiv cov cuab yeej muaj zog hardness, siab hnav tsis kam thiab adhesion tsis kam, xws li tungsten cobalt carbide cov cuab yeej lossis cov cuab yeej coated.

• Txhim kho cov txheej txheem kev npaj: tsim cov txheej txheem txheej txheem kom ntxaws thiab tsim nyog, tsim kom muaj txheej txheem roughing, semi-finishing thiab tiav cov txheej txheem, thiab tawm ntawm cov txheej txheem ua tiav ntawm 0.5-1mm rau kev ua haujlwm siab tom qab.

• Npaj cov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob

Cov txheej txheem tswj

• Txhim kho qhov txiav tsis zoo: Txiav txim siab qhov kev txiav kom tsim nyog los ntawm kev sim thiab kev sib sau ua ke. Feem ntau hais lus, kev siv cov kev txiav qis qis, cov khoom noj nruab nrab thiab cov txiav me me tuaj yeem txo cov cuab yeej hnav thiab ua haujlwm deformation.

• Kev siv cov dej txias uas tsim nyog: kev siv cov kua ua kom txias thiab lubrication zoo, xws li emulsion uas muaj cov khoom siv siab heev lossis cov khoom siv hluavtaws, tuaj yeem txo qhov kub thiab txias, txo qhov kev sib txhuam ntawm cov cuab yeej thiab cov khoom ua haujlwm, inhibit qhov tsim ntawm cov qog nqaij hlav, yog li kev txhim kho kev ua haujlwm raug.

• Cov cuab yeej txoj kev optimization: Thaum lub sij hawm programming, lub cuab tam txoj kev yog optimized, thiab ib tug tsim nyog txiav hom thiab trajectory yog saws kom tsis txhob ntse tig ntawm lub cuab tam thiab nquag acceleration thiab deceleration, txo qhov hloov pauv ntawm txiav quab yuam, thiab txhim kho qhov zoo thiab qhov tseeb ntawm machining nto.

• Kev ua raws li kev tshawb nrhiav hauv online thiab kev them nyiaj: nruab nrog kev tshawb nrhiav hauv online, saib xyuas lub sijhawm ua haujlwm ntawm qhov loj me thiab cov duab tsis zoo hauv cov txheej txheem ntawm kev ua, kev hloov kho raws sij hawm ntawm lub cuab yeej txoj hauj lwm lossis kev ua haujlwm tsis raws li qhov kev kuaj pom, kev them nyiaj yuam kev.

tom qab ua tiav

• Kev ntsuas qhov tseeb: Siv CMM, profiler thiab lwm yam khoom siv ntsuas qhov tseeb los ntsuas cov khoom ua haujlwm tom qab ua tiav, tau txais cov ntaub ntawv loj thiab cov duab zoo, thiab muab lub hauv paus rau kev ntsuas qhov tseeb tom qab thiab kev tswj kom zoo.

• Kev soj ntsuam yuam kev thiab kev hloov kho: Raws li kev ntsuas ntsuas, txheeb xyuas qhov ua rau kev ua haujlwm tsis raug, xws li cov cuab yeej hnav, txiav quab yuam deformation, thermal deformation, thiab lwm yam, thiab siv cov kev ntsuas tsim nyog los kho thiab txhim kho, xws li hloov cov cuab yeej, optimizing kev siv tshuab, kho tshuab tsis, thiab lwm yam.

Post lub sij hawm: Dec-20-2024