CNC machining yog inarguably lub neej ntawm kev tsim kev lag luam nrog kev siv xws li aerospace, kho mob, thiab electronics. Nyob rau hauv xyoo tas los no, muaj kev nce qib zoo kawg hauv kev ua haujlwm ntawm CNC machining cov ntaub ntawv. Lawv cov ntaub ntawv dav dav tam sim no muaj kev sib txuas zoo ntawm cov khoom siv, nqi, thiab kev zoo nkauj.

Nyob rau hauv tsab xov xwm no, peb yuav delve rau hauv ntau lub ntiaj teb no ntawm CNC cov ntaub ntawv. Peb yuav muab cov lus qhia dav dav rau koj los xaiv cov ntaub ntawv zoo rau CNC machining, suav nrog cov ncauj lus kom ntxaws ntawm cov ntaub ntawv siv feem ntau. Tsis tas li ntawd, peb yuav kov cov ntaub ntawv tsawg dua uas koj yuav tsis tau xav txog ua ntej.

Machining Ib puag ncig

Nws yog ib qho tseem ceeb kom xav txog qhov chaw machining thaum xaiv cov khoom siv CNC. Vim tias cov ntaub ntawv sib txawv teb sib txawv rau qhov sib txawv machining, xws li kev txiav ceev, cov cuab yeej siv, thiab cov dej txias. Lub machining ib puag ncig muaj xws li qhov kub thiab txias, av noo, thiab muaj cov kab mob sib kis.

Piv txwv li, qee cov ntaub ntawv yuav muaj lub siab xav nti lossis tawg yog tias lub tshuab ua haujlwm kub dhau, thaum lwm tus yuav muaj kev siv ntau dhau yog tias qhov kev txiav ceev dhau lawm. Ib yam li ntawd, kev siv cov coolants los yog lubricants tej zaum yuav tsim nyog los txo cov cua sov thiab kev sib txhuam thaum lub sij hawm machining. Tab sis cov no yuav tsis sib haum nrog qee cov ntaub ntawv thiab yuav ua rau corrosion lossis lwm yam kev puas tsuaj.

Yog li ntawd, coj mus rau hauv tus account lub machining ib puag ncig tuaj yeem pab txhim kho cov khoom tsim tau, txo cov nqi, thiab xyuas kom zoo ntawm cov khoom tiav.

Qhov hnyav

Nws yog ib qho tseem ceeb uas yuav tsum xav txog qhov hnyav ib feem kom ntseeg tau tias tus nqi zoo, kev ua tau zoo, thiab kev tsim khoom. Cov khoom hnyav dua yuav tsum muaj cov khoom siv ntau dua, uas tuaj yeem ua rau tus nqi ntau lawm. Tsis tas li ntawd, qhov hnyav dua yuav xav tau cov tshuab CNC loj dua thiab muaj zog dua los tsim, uas ua rau cov nqi thiab sijhawm ntau lawm. Yog li ntawd, xaiv cov khoom siv nrog qhov tsawg tsawg, xws li txhuas lossis magnesium, tuaj yeem pab txo qhov hnyav ntawm qhov thiab txo cov nqi tsim khoom.

Tsis tas li ntawd, qhov hnyav ib feem kuj tuaj yeem cuam tshuam kev ua haujlwm ntawm cov khoom kawg. Piv txwv li, hauv kev siv aerospace, txo qhov hnyav ntawm ib feem tuaj yeem ua rau kom muaj roj thiab txhim kho kev ua haujlwm tag nrho. Hauv kev siv tsheb, txo qhov hnyav kuj tuaj yeem txhim kho roj efficiency, nrog rau kev ua kom nrawm thiab tuav.

Thaum tshav kub kub Resistance

Thaum tshav kub kub tsis kam cuam tshuam ncaj qha rau cov khoom muaj peev xwm tiv taus qhov kub thiab txias yam tsis muaj qhov cuam tshuam loj heev los yog kev puas tsuaj. Thaum lub sij hawm CNC machining txheej txheem, cov khoom raug machined undergoes ntau yam cua sov thiab txias mus, tshwj xeeb tshaj yog thaum nws raug txiav, drilled, los yog milled. Cov voj voog no tuaj yeem ua rau thermal expansion, warping, los yog tawg hauv cov ntaub ntawv uas tsis muaj cua sov.

Xaiv cov khoom siv CNC nrog cov cua kub zoo kuj tuaj yeem pab txhim kho cov txheej txheem machining thiab txo cov nqi tsim khoom. Thaum cov khoom tuaj yeem tiv taus qhov kub thiab txias, nws tso cai rau kev txiav nrawm dua thiab txiav tob dua. Qhov no coj lub sij hawm machining luv dua thiab txo qhov hnav ntawm cov cuab yeej.

Cov ntaub ntawv sib txawv rau CNC machining muaj qhov sib txawv ntawm cov cua sov ua haujlwm, thiab kev xaiv ntawm cov khoom yog nyob ntawm kev npaj siv cov khoom tiav. Cov ntaub ntawv zoo li txhuas thiab tooj liab yog tsim rau cov dab dej kub thiab thermal tswj kev siv vim lawv cov thermal conductivity zoo. Tab sis stainless hlau thiab titanium yog zoo tagnrho rau aerospace thiab kev kho mob daim ntawv thov vim lawv cov ntsiab lus melting siab thiab corrosion kuj.

Hluav taws xob conductivity thiab sib nqus yuav tsum tau

Hluav taws xob conductivity yog ib qho kev ntsuas ntawm cov khoom muaj peev xwm ua hluav taws xob. Hauv CNC machining, cov ntaub ntawv uas muaj hluav taws xob muaj hluav taws xob zoo dua vim tias lawv tuaj yeem ua kom sov tau zoo. Qhov no yog ib qho tseem ceeb tshwj xeeb tshaj yog thaum machining hlau, vim hais tias cov cua sov tsim thaum lub sij hawm tus txheej txheem yuav ua rau cov khoom mus rau warp los yog deform. Cov ntaub ntawv uas muaj hluav taws xob siab, xws li tooj liab thiab txhuas, tuaj yeem ua kom sov tau zoo, uas pab tiv thaiv cov teeb meem no.

Cov khoom sib nqus kuj tseem ceeb thaum xaiv cov khoom siv CNC, tshwj xeeb tshaj yog thaum ua haujlwm nrog cov ntaub ntawv ferromagnetic xws li hlau, npib tsib xee, thiab cobalt. Cov ntaub ntawv no muaj lub zog sib nqus uas tuaj yeem cuam tshuam cov txheej txheem txiav. Cov ntaub ntawv uas tsis yog hlau nplaum, xws li titanium thiab stainless hlau, yog nyiam rau CNC machining. Vim tias lawv tsis cuam tshuam los ntawm cov hlau nplaum thiab yog li tsim kom muaj kev ntxuav huv.

Hardness

Machinability hais txog qhov yooj yim npaum li cas cov khoom tuaj yeem raug txiav, drilled, lossis zoo li tus CNC tshuab cuab yeej.

Thaum cov khoom siv CNC nyuaj dhau, nws tuaj yeem nyuaj rau kev txiav lossis cov duab, uas tuaj yeem ua rau cov cuab yeej siv ntau dhau, cov cuab yeej tawg, lossis cov khoom tsis zoo. Piv txwv li, cov khoom uas muag muag heev yuav deform los yog deflect nyob rau hauv lub txiav quab yuam, ua rau tsis zoo qhov tseeb qhov tseeb los yog nto tiav.

Yog li ntawd, xaiv cov khoom siv rau CNC machining nrog qhov tsim nyog hardness yog qhov tseem ceeb rau kev ua tiav cov khoom zoo, precision machined Cheebtsam. Tsis tas li ntawd, qhov hardness ntawm cov khoom kuj tuaj yeem cuam tshuam qhov ceev thiab kev ua haujlwm ntawm cov txheej txheem machining. Vim tias cov ntaub ntawv nyuaj yuav xav tau kev txiav qeeb qeeb lossis cov cuab yeej txiav muaj zog dua.

Nto tiav

Qhov saum npoo tiav cuam tshuam rau qhov kawg machined khoom qhov kev ua tau zoo thiab cov tsos. Piv txwv li, ib feem nrog qhov ntxhib saum npoo tiav yuav muaj kev sib txhuam ntau dua, uas tuaj yeem ua rau hnav ntxov ntxov thiab ua tsis tiav. Ntawm qhov tod tes, ib feem nrog lub ntsej muag du yuav muaj kev sib txhuam tsawg, uas ua rau kev ua haujlwm zoo dua qub thiab lub neej ntev dua. Tsis tas li ntawd, qhov saum npoo tiav kuj plays lub luag haujlwm tseem ceeb hauv kev zoo nkauj. Lub polished nto tiav tuaj yeem txhim kho cov tsos ntawm ib feem thiab ua rau nws txaus siab rau cov neeg siv khoom.

Yog li ntawd, thaum xaiv cov khoom siv rau CNC machining, nws yog ib qho tseem ceeb uas yuav tau xav txog qhov yuav tsum tau ua tiav ntawm cov khoom kawg. Qee cov khoom siv tau yooj yim rau kev siv lub tshuab ua kom zoo nkauj zoo nkauj dua li lwm tus. Piv txwv li, cov hlau xws li txhuas thiab tooj dag yog qhov yooj yim rau tshuab kom ua tiav. Hauv qhov sib piv, cov ntaub ntawv xws li carbon fiber thiab fiberglass tuaj yeem nyuaj rau lub tshuab, thiab ua kom tiav qhov kev ua tiav zoo yuav xav tau cov cuab yeej tshwj xeeb thiab cov tswv yim.

Kev zoo nkauj

Yog tias koj txoj haujlwm CNC machining yog npaj los tsim cov khoom lag luam uas yuav siv rau hauv qhov chaw muag khoom siab, kev zoo nkauj yuav yog qhov tseem ceeb. Cov khoom yuav tsum visually txaus siab, nrog ib tug txaus nyiam kev ntxhib los mos, xim, thiab nto finish. Nws tseem yuav tsum muaj peev xwm ua tau yooj yim polished, pleev xim rau, lossis ua tiav kom ua tiav qhov xav tau.

Tsis tas li ntawd, hauv kev lag luam xws li automotive thiab aerospace, kev zoo nkauj tuaj yeem yog qhov qhia txog cov khoom zoo thiab cov chaw tsim khoom kom paub meej. Qhov no yog qhov tshwj xeeb tshaj yog nyob rau hauv cov khoom kim heev, qhov twg cov neeg siv khoom them tus nqi rau cov khoom zoo thiab ua tiav.

Daim ntawv thov

Daim ntawv thov zaum kawg ntawm cov khoom yog qhov kawg ntawm kev txiav txim siab. Cov ntsiab lus hais saum toj no ua ib feem me me ntawm txhua qhov laj thawj uas ib tus xav txog ua ntej ua tiav cov khoom siv CNC. Lwm yam kev thov-tsav tau muaj xws li kev txhawj xeeb xws li cov khoom siv machinability, tshuaj reactivity, adhesiveness, khoom muaj, qaug zog lub neej, thiab lwm yam.

Thaum nws los txog rau kev xaiv cov ntaub ntawv tsim nyog rau CNC machining, lub hom phiaj ntawm daim ntawv thov ntawm cov khoom tiav yog ib qho tseem ceeb uas yuav tau xav txog. Cov khoom sib txawv muaj qhov sib txawv, xws li hardness, tensile zog, thiab ductility. Cov khoom no cuam tshuam li cas cov khoom ua tau raws li cov xwm txheej tshwj xeeb thiab txiav txim siab qhov tsim nyog ntawm cov khoom siv rau kev siv sib txawv.

Piv txwv li, yog tias cov khoom tiav yog npaj rau kev siv nyob rau hauv ib puag ncig kub, cov ntaub ntawv xws li txhuas los yog tooj liab yuav yog ib qho kev xaiv zoo dua vim lawv cov thermal conductivity siab thiab tsis kam ua rau kub puas.

Nyiaj txiag

Nyiaj txiag yog ib qho tseem ceeb uas yuav tau xav txog ntau yam. Ua ntej, cov khoom siv tus nqi tuaj yeem sib txawv nyob ntawm seb hom thiab ntau npaum li cas. Txawm hais tias qee cov hlau qib siab yuav raug nqi, cov yas lossis cov khoom sib xyaw tuaj yeem pheej yig dua. Kev teeb tsa cov peev nyiaj rau cov ntaub ntawv yuav pab txo qis koj cov kev xaiv thiab tsom mus rau cov khoom hauv koj cov nqi ntau.

Qhov thib ob, tus nqi machining ntawm CNC tuaj yeem kim thiab siv sijhawm ntev. Tus nqi machining nyob ntawm cov khoom siv, qhov nyuaj ntawm qhov, thiab cov cuab yeej xav tau. Xaiv cov ntaub ntawv uas pheej yig dua rau lub tshuab tuaj yeem ua rau tag nrho cov nqi tsim khoom qis.

Thaum kawg, xaiv cov ntaub ntawv uas nyob hauv koj cov peev nyiaj tuaj yeem cuam tshuam cov khoom tiav qhov zoo. Cov ntaub ntawv pheej yig dua tuaj yeem ua rau muaj qhov tsis xws lossis tsawg dua cov khoom siv zoo dua. Yog li ntawd, teeb tsa cov peev nyiaj thiab xaiv cov khoom siv zoo dua hauv cov peev nyiaj yuav ua kom cov khoom tiav yog ob qho tib si ruaj thiab cov qauv siab.

Cov ntaub ntawv zoo tshaj plaws rau CNC Machining Projects

Tam sim no, cia peb mus rau qhov txuas ntxiv ntawm peb qhov kev sib tham: hom CNC machining cov ntaub ntawv. Peb yuav tham txog kev nthuav dav ntawm cov hlau tsis tu ncua thiab cov yas. Tom qab ntawd, peb yuav hloov peb txoj kev tsom mus rau qee cov ntaub ntawv tsis paub CNC.

Cov khoom siv hlau CNC

Hlau yog cov khoom siv tshaj plaws ntawm CNC machined qhov chaw. Lawv muaj ntau yam khoom zoo xws li siab zog, hardness, thermal kuj, thiab hluav taws xob conductivity.

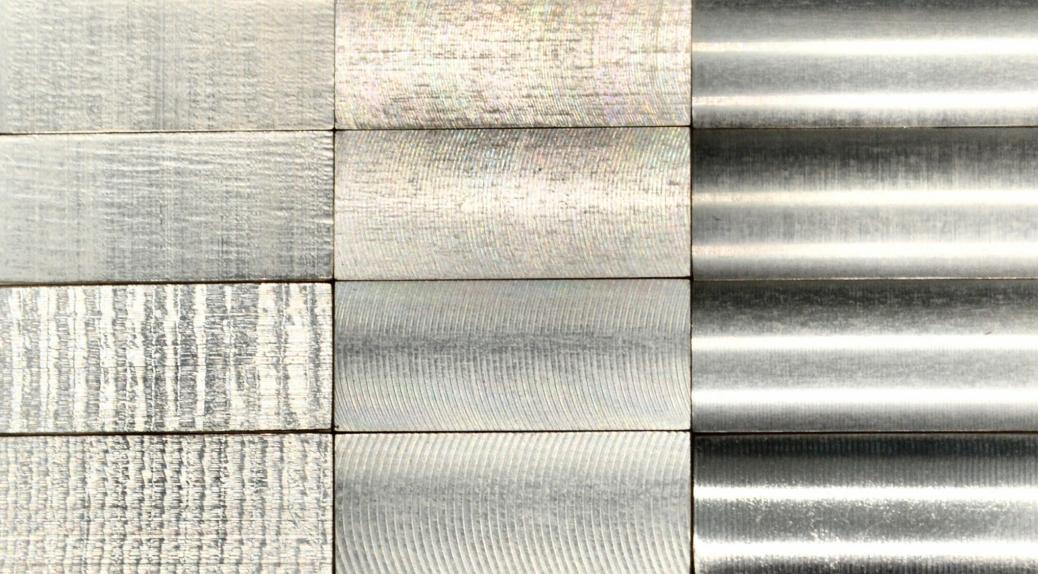

Aluminium (6061, 7075)

Aluminium yog dav suav hais tias yog ib qho ntawm cov khoom siv ntau yam thiab muaj txiaj ntsig hauv CNC machining. Nws muaj qhov tshwj xeeb lub zog-rau-qhov hnyav piv, lub teeb yuag, kev tiv thaiv corrosion, thiab zoo nkauj silvery. Yog li, aluminium yog qhov tsim nyog rau kev siv ntau yam kev siv. Tsis tas li ntawd, nws cov khoom zoo thermal thiab hluav taws xob ua rau nws zoo tagnrho rau kev siv hauv ntau yam kev siv hluav taws xob thiab thermal tswj kev siv.

Piv nrog rau lwm yam CNC hlau, xws li titanium thiab hlau, txhuas yog ib qho yooj yim rau tshuab, uas ua rau nws yog ib tug nrov kev xaiv rau manufacturers. Txawm li cas los xij, nws yuav tsum raug sau tseg tias aluminium tsis yog cov khoom siv pheej yig tshaj plaws. Thiab nws yog kim dua li lwm yam khoom siv, xws li stainless hlau.

Cov qib siab zoo 6061 thiab 7075 ntawm aluminium yog tshwj xeeb tshaj yog nrov rau siv nyob rau hauv aerospace thav duab, automotive engine qhov chaw, thiab lub teeb yuag khoom. Txawm li cas los xij, aluminium versatility txhais tau hais tias nws yog siv nyob rau hauv ntau lwm yam lag luam thiab kev siv, nrog rau kev tsim kho, ntim, thiab cov neeg siv khoom siv hluav taws xob.

Stainless hlau (316, 303, 304)

Stainless hlau tuaj nyob rau hauv ntau qib. Feem ntau, txawm li cas los xij, nws muaj lub zog siab thiab tawv, hnav tsis kam, thiab corrosion kuj, thiab muaj qhov ci zoo li txhuas. Tsis tas li ntawd, nws yog nyob rau hauv nruab nrab nqi hlau. Txawm li cas los xij, nws yog ib qho nyuaj-rau-tshuab CNC khoom vim nws hardness.

316 SS muaj txiaj ntsig zoo hauv kev siv dej hiav txwv, khoom siv kho mob, thiab cov ntaub thaiv sab nraum zoov vim nws muaj peev xwm tiv taus cua sov thiab xeb. 303 thiab 314 sib koom cov khoom sib xws thiab feem ntau pheej yig dua thiab siv tau ntau dua li 316. Lawv qhov kev siv tseem ceeb suav nrog cov fasteners (bolts, screws, bushings, thiab lwm yam), cov khoom siv hauv tsheb, thiab cov khoom siv hauv tsev.

Carbon Steel thiab Alloy Steel

Cov pa roj carbon steel thiab lwm yam alloys muaj lub zog zoo thiab ua haujlwm tau zoo, ua rau lawv zoo tagnrho rau kev siv ntau yam. Lawv kuj sib xws nrog ntau yam txheej txheem kho cua sov, ntxiv dag zog rau lawv cov khoom siv kho tshuab. Ntxiv mus, carbon steel kuj pheej yig piv rau lwm yam CNC hlau.

Txawm li cas los xij, nws tsim nyog sau cia tias cov pa roj carbon steel thiab nws cov alloys tsis tuaj yeem tiv taus corrosion, tsis zoo li cov ntaub ntawv xws li stainless hlau lossis txhuas. Tsis tas li ntawd, lawv cov tsos ntxhib yuav tsis haum rau kev zoo nkauj.

Txawm li cas los xij, cov pa roj carbon steel thiab nws cov alloys muaj ntau yam kev siv, nrog rau cov tshuab fasteners thiab cov khoom siv xws li kab teeb. Txawm hais tias lawv cov kev txwv, cov ntaub ntawv no tseem yog qhov kev xaiv nrov rau ntau qhov kev lag luam thiab kev tsim khoom vim lawv lub zog, pheej yig, thiab machinability.

tooj dag

Brass yog cov hlau ntau yam paub txog nws cov machinability zoo, corrosion kuj, thiab thermal thiab hluav taws xob conductivity. Nws kuj boasts ib tug txaus nyiam tsos ua tsaug rau nws cov ntsiab lus tooj liab, raws li zoo raws li zoo heev nto kev sib txhuam zog.

Brass pom ntau daim ntawv thov hauv ntau yam kev lag luam. Piv txwv li, nws yog feem ntau siv rau hauv cov khoom siv, cov khoom siv tsis muaj zog, cov kav dej, thiab cov khoom siv hluav taws xob. Nws cov khoom ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev tsim cov khoom lag luam uas xav tau kev ua haujlwm ntev thiab lub zog thaum tuav qhov kev zoo nkauj.

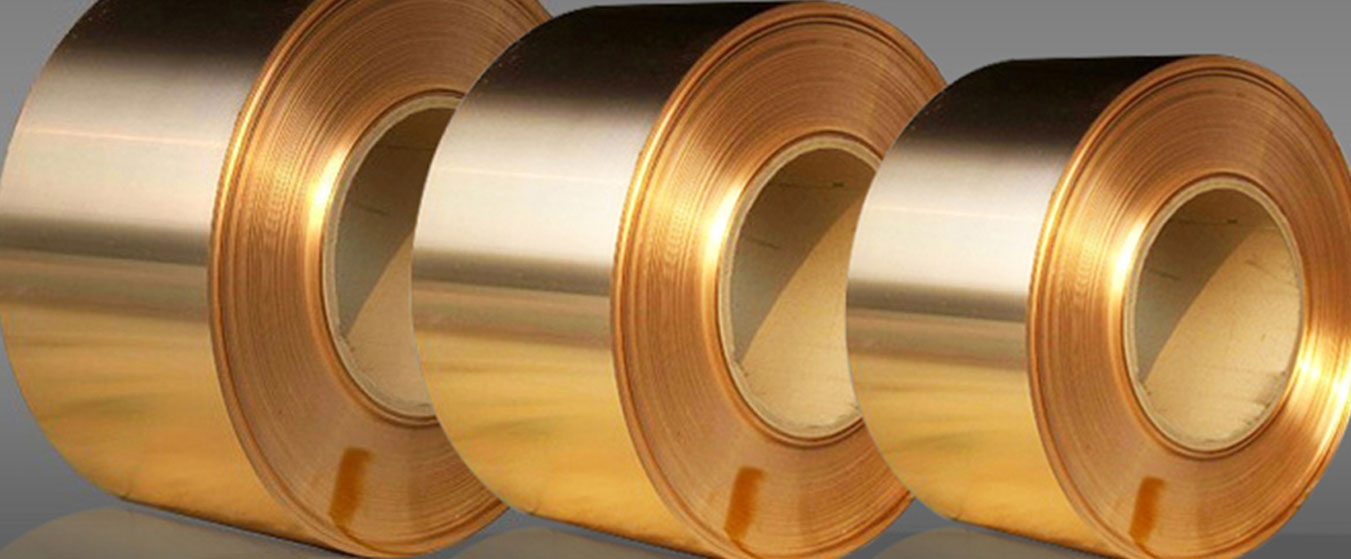

Tooj

Copper muaj npe nrov rau nws cov hluav taws xob zoo heev thiab thermal conductivity. Txawm li cas los xij, nws tuaj yeem nyuaj rau lub tshuab vim nws qhov siab malleability. Qhov no tuaj yeem ua rau muaj teeb meem hauv kev tsim cov chips thaum CNC machining. Tsis tas li ntawd, tooj liab yog qhov ua rau corrosion, uas tuaj yeem ua rau muaj kev txhawj xeeb hauv qee qhov chaw.

Txawm hais tias muaj kev sib tw no, tooj liab tau siv dav hauv ntau qhov kev lag luam, nrog rau kev siv hluav taws xob, cov khoom sib nqus, thiab kev tsim cov hniav nyiaj hniav kub. Nws cov khoom siv hluav taws xob zoo heev ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev siv hluav taws xob thiab hluav taws xob, thaum nws txoj kev zoo nkauj thiab kev zoo nkauj ua rau nws muaj kev xaiv nrov hauv kev lag luam hniav nyiaj hniav kub.

Titanium

Titanium alloys paub txog lawv qhov tshwj xeeb lub zog-rau-hnyav piv, ua rau lawv hnav thiab muaj zog ib txhij. Lawv kuj yog corrosion-resistant thiab muaj zoo tshav kub conductivity. Tsis tas li ntawd, titanium yog biocompatible, yog li lawv tsim nyog rau kev siv biomedical.

Txawm li cas los xij, muaj qee qhov tsis zoo rau kev siv titanium. Nws muaj hluav taws xob conductivity tsis zoo thiab nyuaj rau tshuab. HSS tsis tu ncua los yog tsis muaj zog carbide cutters tsis haum rau machining nws, thiab nws yog ib qho khoom kim heev los siv hauv CNC manufacturing.

Txawm li cas los xij, titanium yog cov khoom siv nrov rau CNC machining, tshwj xeeb tshaj yog rau cov khoom siv hauv aerospace, cov khoom siv tub rog, thiab cov khoom siv biomedical xws li cog.

Magnesium

Magnesium yog cov hlau uas sib xyaw ua ke nrog lub zog qis. Nws zoo heev thermal zog ua rau nws zoo tagnrho rau siv nyob rau hauv high-kub ib puag ncig, xws li nyob rau hauv lub cav. Nws lub teeb yuag tso cai rau kev tsim cov tsheb sib dua thiab siv roj ntau dua.

Txawm li cas los xij, magnesium tseem paub txog nws qhov flammability, uas tuaj yeem ua rau muaj kev txhawj xeeb txog kev nyab xeeb hauv qee yam kev siv. Tsis tas li ntawd, nws tsis yog corrosion-resistant ib co lwm yam hlau, xws li txhuas, thiab yuav kim dua rau tshuab.

Cov khoom siv yas CNC

Peb tam sim no yuav tham txog CNC yas. Txawm hais tias feem ntau cov ntaub ntawv yas tsis yog machinable vim lawv cov rigidity tsawg thiab melting cov ntsiab lus, peb tau xaiv tawm cov pab pawg me uas muaj ntau yam kev siv CNC.

Acetal (POM)

Acetal yog ntau yam CNC yas nrog ntau yam khoom tsim nyog. Nws boasts zoo heev qaug zog thiab cuam tshuam tsis kam, zoo toughness, thiab tsis tshua muaj kev sib txhuam coefficients. Tsis tas li ntawd, nws muaj peev xwm tiv taus cov dej noo, uas ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev siv hauv qhov chaw ntub dej.

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm acetal yog nws cov rigidity, uas ua rau nws yooj yim rau tshuab nrog qhov tseeb qhov tseeb. Qhov no ua rau nws yog qhov kev xaiv nrov rau kev siv hauv cov khoom precision xws li bearings, gears, thiab li qub. Vim nws cov khoom siv zoo heev thiab kev ua haujlwm siab rau ib puag ncig, Acetal yog qhov kev xaiv zoo rau ntau yam lag luam, xws li tsheb, aerospace, thiab cov khoom siv.

Acrylic (PMMA)

Acrylic yog cov khoom siv feem ntau uas tuaj yeem ua haujlwm hloov iav vim nws cov khoom tsim nyog. Nws muaj qhov zoo rigidity thiab optical clarity, tso cai rau nws siv nyob rau hauv daim ntawv thov qhov twg pom-los ntawm qhov chaw yog tsim nyog. Acrylic Cheebtsam muab ib qho kev ntxim nyiam thiab ua haujlwm zoo rau iav, nrog rau qhov pom kev pom zoo thiab muaj kev ua haujlwm siab.

Thaum acrylic muaj qee qhov kev txwv, xws li nws qhov cuam tshuam rau kev tawg thiab thermal softening, nws tseem yog cov khoom siv nrov rau CNC machining vim nws ntau yam thiab yooj yim ntawm kev siv. Nrog lub peev xwm los tsim cov khoom zoo, cov khoom zoo, acrylic yog qhov kev xaiv zoo tshaj plaws rau ntau yam kev siv. Cov tsom iav, cov ntaub thaiv npog, cov thawv ntim khoom noj, thiab cov khoom zoo nkauj tsuas yog qee qhov piv txwv.

Polycarbonate (PC)

Polycarbonate (PC) yog cov khoom siv yas nrov siv rau CNC machining vim nws cov khoom tshwj xeeb. Nws yog pob tshab heev, ua rau nws yog ib qho khoom siv zoo tshaj plaws rau kev siv hauv cov khoom uas xav tau kom pom tseeb, xws li tsom iav kev nyab xeeb, khoom siv kho mob, thiab cov khoom siv hluav taws xob. Tsis tas li ntawd, nws muaj qhov ua kom sov zoo yog li nws tsim nyog siv rau hauv cov ntawv thov kub.

Txawm li cas los xij, nws qhov cuam tshuam rau khawb thiab tsis muaj UV tiv thaiv tuaj yeem txwv nws siv hauv qee yam kev siv. Kev raug tshav ntuj ntev ntev tuaj yeem ua rau nws daj thiab ua nkig. Qhov no tuaj yeem txwv tsis pub siv rau sab nraum zoov tshwj tsis yog nws hloov kho nrog UV stabilizers.

Ib qho kev siv ntawm PC yog nyob rau hauv kev tsim cov tsom iav kev nyab xeeb thiab lub ntsej muag shields, qhov twg nws cuam tshuam tsis kam thiab pob tshab ua rau nws yog qhov kev xaiv zoo tshaj plaws. PC kuj tseem siv los tsim cov khoom siv tsheb, cov khoom siv hluav taws xob, thiab cov khoom siv kho mob.

Polypropylene (PP)

Polypropylene yog ntau yam polymer nrog ntau cov txiaj ntsig, suav nrog cov tshuaj lom neeg muaj zog thiab qaug zog. Nws tseem yog cov khoom siv kho mob qib, thiab nws ua rau lub ntsej muag du thaum CNC machining. Txawm li cas los xij, ib qho ntawm nws cov kev txwv yog tias nws tsis tuaj yeem tiv taus qhov kub thiab txias, vim nws zoo li muag muag thiab gallbladder thaum txiav, uas ua rau nws nyuaj me ntsis rau lub tshuab.

Polypropylene tseem yog qhov kev xaiv nrov rau ntau yam kev siv. Nws cov khoom zoo heev ua rau nws tsim nyog rau kev ua cov iav thiab cov khoom siv kho mob.

ABS

ABS yog ib qho khoom siv zoo heev uas muaj txiaj ntsig zoo rau CNC machining vim nws txoj kev ua haujlwm zoo, lub zog tensile, cuam tshuam tsis kam, thiab tshuaj lom neeg tsis kam. Tsis tas li ntawd, nws tuaj yeem ua xim yooj yim, ua rau nws zoo tagnrho rau cov ntawv thov uas qhov kev zoo nkauj tseem ceeb.

Txawm li cas los xij, ABS tsis haum rau siv nyob rau hauv qhov chaw kub kub thiab tsis yog biodegradable. Tsis tas li ntawd, nws tsim cov pa taws tsis zoo thaum hlawv, uas tuaj yeem ua rau muaj kev txhawj xeeb hauv lub khw CNC.

ABS muaj ntau daim ntawv thov thiab feem ntau siv hauv 3D luam ntawv thiab txhaj tshuaj molding, feem ntau nrog kev ua haujlwm tom qab siv CNC machining. Nws nquag siv los tsim cov khoom siv hauv tsheb, thiab cov ntaub thaiv npog, thiab rau kev tsim qauv sai.

Nylon

Nylon yog cov khoom siv ntau yam nrog lub zog tensile zoo, hardness, thiab kev cuam tshuam tsis kam. Nws tuaj yeem siv tau ntau yam ntaub ntawv sib xyaw, xws li iav-fiber-reinforced nylon, thiab muaj peev xwm lubrication zoo heev. Txawm li cas los xij, nws tsis pom zoo siv rau hauv qhov chaw ntub dej.

Nylon yog qhov tshwj xeeb zoo rau cov ntawv thov uas xav tau kev tiv thaiv los ntawm kev sib txhuam. Qhov no suav nrog cov khoom xws li iav, zawv zawg qhov chaw, bearings, thiab sprockets. Nrog nws lub zog zoo tshaj thiab lubrication zog, nylon yog qhov kev xaiv nrov rau ntau yam khoom lag luam thiab kev ua kis las.

UHMW-PE

UHMWPE yog cov khoom siv nrov vim nws cov khoom tshwj xeeb, suav nrog kev ua haujlwm siab, puas thiab hnav tsis kam thiab ua haujlwm ntev. Txawm li cas los xij, nws cov thermal instability thaum machining ua rau nws nyuaj rau tshuab.

Txawm hais tias nws nyuaj rau kev ua haujlwm, UHMWPE yog cov khoom siv zoo heev rau CNC machining ntawm zawv zawg qhov chaw hauv bearings, gears, thiab rollers. Nws cov khoom zoo tshaj plaws ua rau nws zoo tagnrho rau cov ntawv thov uas yuav tsum muaj kev hnav siab thiab ua haujlwm ntev. Thaum machined kom raug, UHMWPE tuaj yeem muab kev ua tau zoo thiab lub neej ntev dua piv rau lwm cov ntaub ntawv.

Lwm yam khoom siv

CNC machining feem ntau siv hlau thiab yas, tab sis nws tuaj yeem ua haujlwm nrog ntau lwm cov ntaub ntawv, suav nrog cov npe hauv qab no.

Ua npuas ncauj

Foams yog ib hom ntawm CNC khoom uas yog tus yam ntxwv ntawm lub cev muaj zog nrog cov huab cua puv voids. Cov qauv tshwj xeeb no muab cov foams pom zoo thiab zoo kawg nkaus lightness. Qee qhov ua npuas ncauj siab, xws li polyurethane ua npuas ncauj thiab Styrofoam, tuaj yeem ua tau yooj yim vim lawv cov rigidity, lub zog, hnav, thiab ua haujlwm ntev.

Foams 'lub teeb yuag ua rau lawv muaj kev xaiv zoo tshaj plaws rau kev tiv thaiv ntim. Lawv versatility nyob rau hauv raug machined rau hauv ntau yam duab thiab qhov ntau thiab tsawg ua rau lawv sib npaug pab tau rau tsim cov khoom zoo nkauj. Tsis tas li ntawd, lawv cov khoom siv insulating ua rau lawv muaj kev xaiv zoo rau kev rwb thaiv tsev thermal hauv cov tsev, cov tub yees, thiab lwm yam kev siv uas qhov ntsuas kub tseem ceeb.

Ntoo

Ntoo yog cov khoom siv dav siv rau CNC machining vim nws qhov yooj yim ntawm machining, zoo zog thiab hardness, thiab ntau hom muaj. Tsis tas li ntawd, ntoo yog cov organic compound thiab tsis muaj kev cuam tshuam rau ib puag ncig. Vim nws txoj kev ua kom zoo nkauj thiab zoo nkauj, ntoo yog qhov kev xaiv nrov rau rooj tog, tsev décor, thiab DIY tej yaam num.

Txawm li cas los xij, kev siv ntoo ua kom muaj plua plav ntau, uas tuaj yeem ua rau muaj kev phom sij rau cov neeg ua haujlwm. Yog li ntawd, nws yog ib qho tseem ceeb rau kev cob qhia wood machining kom muaj kev tswj xyuas zoo nyob rau hauv qhov chaw.

Composites

Composites yog cov khoom tsim los ntawm ob lossis ntau qhov sib xyaw uas tau koom ua ke nrog kev sib txuas nruab nrab. Cov ntaub ntawv sib xyaw uas siv hauv CNC machining muaj xws li carbon fiber, plywood, fiberglass, thiab lwm yam. Cov ntaub ntawv no muaj kev siv ntau yam kev lag luam, xws li tsheb, aviation, kis las, thiab kev kho mob.

Machining composites tuaj yeem nyuaj heev vim muaj ntau yam. Cov khoom siv hauv cov khoom sib xyaw tuaj yeem muaj cov khoom sib txawv thiab cov ntaub ntawv, xws li fibers, shards, lossis daim hlau. Dab tsi ntxiv, qhov sib txuas nruab nrab nws tus kheej tuaj yeem muaj cov khoom tshwj xeeb uas yuav tsum tau coj mus rau hauv tus account thaum lub sijhawm machining txheej txheem.

Tsis txhob hnov qab xav txog cov khoom muaj peev xwm CNC

Cov nplua nuj ntau yam hauv CNC machining cov ntaub ntawv tuaj yeem ua rau muaj kev ntxhov siab ntau dua li cov txiaj ntsig. Nws yog ib qho teeb meem tshwm sim los saib xyuas cov khoom siv CNC tshaj li cov pa hlau thiab cov yas.

Txhawm rau pab koj saib daim duab loj dua thaum Tsim Kev Tsim Khoom, hauv qab no yog cov npe luv luv ntawm cov ntsiab lus los xav txog ua ntej ua tiav cov ntaub ntawv rau koj qhov project!

Xaiv cov khoom siv tsis yog xim hlau: Muaj ntau qhov xwm txheej uas cov khoom tsis yog xim hlau sib npaug sib npaug rau cov hlau. Cov yas tawv zoo li ABS lossis UHMW-PE yog cov tawv tawv, muaj zog, thiab ruaj khov, piv txwv li. Composites xws li carbon fiber kuj yog touted ua superior rau ntau cov hlau ua tau zoo tshaj plaws.

Xav txog Phenolics: Phenolics yog ib hom khoom siv uas muaj txiaj ntsig zoo nrog cov rigidity siab thiab cov khoom nto. Lawv yooj yim rau tshuab thiab tuaj yeem txiav ntawm qhov nrawm heev, txuag lub sijhawm thiab nyiaj txiag.

Paub cov yas sib txawv: Kev paub txog tag nrho cov ntaub ntawv ntawm cov yas CNC machining cov ntaub ntawv yog ib qho yuav tsum muaj kev txawj rau cov neeg tsim qauv. CNC yas yog pheej yig, yooj yim rau tshuab, thiab tuaj nyob rau hauv ib tug ntau yam ntawm cov khoom siv uas yuav tsis raug ignored.

Xaiv Txoj Cai Ntawm Cov Ncauj Ua Npuas Ncauj: Xa mus rau ntu saum toj no hais txog foams, peb xav hais tias nws muaj peev xwm ua tau ntau yam khoom siv CNC. Txawm tias qee qhov CNC tshuab Cheebtsam yog tam sim no ua los ntawm cov hlau nplaum! Kawm txawv CNC foams kom pom qhov twg haum rau koj daim ntawv thov zoo tshaj.

Txawv CNC Machining Projects thiab cov ntaub ntawv, Ib Qhov Chaw

Tsim rau kev tsim khoom yog ib qho tseem ceeb ntawm kev lag luam niaj hnub no. Raws li cov ntaub ntawv tshawb fawb tau dhau los, CNC machining tau dhau los ua kev cia siab rau kev xav txog kev xaiv cov ntaub ntawv. Ntawm Guan Sheng, peb tshwj xeeb hauv CNC machining cov kev pab cuam, suav nrog CNC milling thiab tig, thiab muab ntau yam khoom siv, los ntawm kev nrhiav-tom qab hlau mus rau cov yas zoo. Peb lub peev xwm 5-axis machining, ua ke nrog peb pab neeg muaj kev paub dhau los, cia peb muab qhov tsis sib xws thiab qhov zoo rau peb cov neeg siv khoom.

Peb mob siab rau muab kev pabcuam tshwjxeeb rau cov neeg siv khoom thiab tau cog lus los pab peb cov neeg siv khoom txo nqi thiab ua tiav lawv cov hom phiaj. Peb pab neeg ua haujlwm muaj peev xwm los pab koj xaiv cov ntaub ntawv zoo tshaj plaws rau koj qhov project thiab tuaj yeem muab cov kws tshaj lij tawm tswv yim pub dawb. Txawm hais tias koj xav tau kev cai CNC machined qhov chaw lossis muaj qhov project tshwj xeeb hauv siab, peb nyob ntawm no los pab koj txhua kauj ruam ntawm txoj kev.

Lub sij hawm xa tuaj: Plaub Hlis-07-2023